22

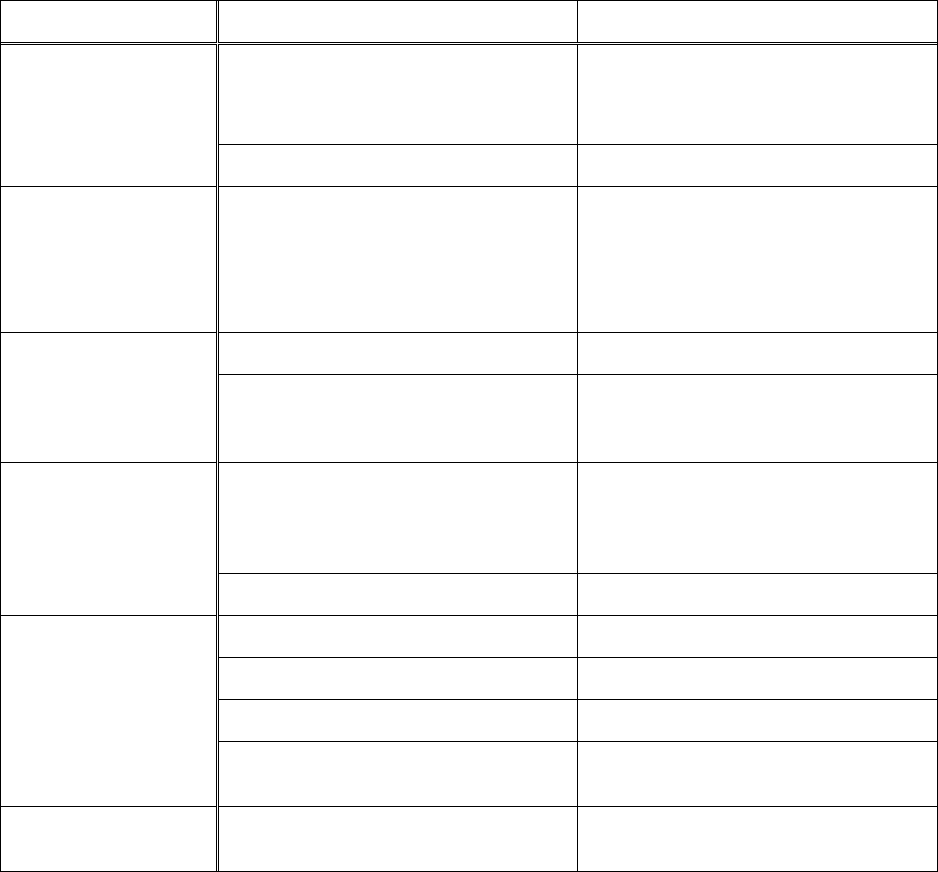

Trouble Probable Cause Remedy [with page #]

Raised areas on

shaped edge.

Variation in pressure which holds

work against cutter.

Keep work firmly against fence or

collars throughout pass.

Use hold-downs or stock feeder. [19]

Excessive feed rate. Decrease feed rate.

Work pulled from

hand.

No support of workpiece.

Use miter gauge with clamp or hold-

down to start cut when shaping

freehand; hold work firmly against

fence.

Adjust tension of spring guard.

Depth of cut not

uniform.

Outfeed fence is misaligned. Adjust outfeed fence.

Side pressure not uniform.

Use hold-downs or stock feeder; keep

pressure against fence or collars

consistent.

Variation in height of

cut. Variation in pressure which holds

work down on table.

Keep pressure firm throughout pass;

use hold-downs; make pass slowly

and steadily. Whenever possible,

keep cutter under stock. [19]

Spindle lock not engaged. Engage spindle lock. [15]

Cuts not smooth. Wrong cutter speed. Use faster RPMs.

Feeding too fast. Pass stock more slowly.

Working against grain. Work with grain whenever possible.

Cutting too deep.

For very deep cuts make several

passes.

Resistance in spindle

while being raised.

Sawdust and/or dirt in raising

mechanisms.

Brush or blow out loose dust and dirt.

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 Monday through Friday (see our website for business hours, www.powermatic.com).

Having the Model Number and Serial Number of your machine available when you call will allow us to

serve you quickly and accurately.