MHD56037 - Edition 5 27

3. Rotating adjustment screw counterclockwise will decrease

pressure required to activate overload valve.

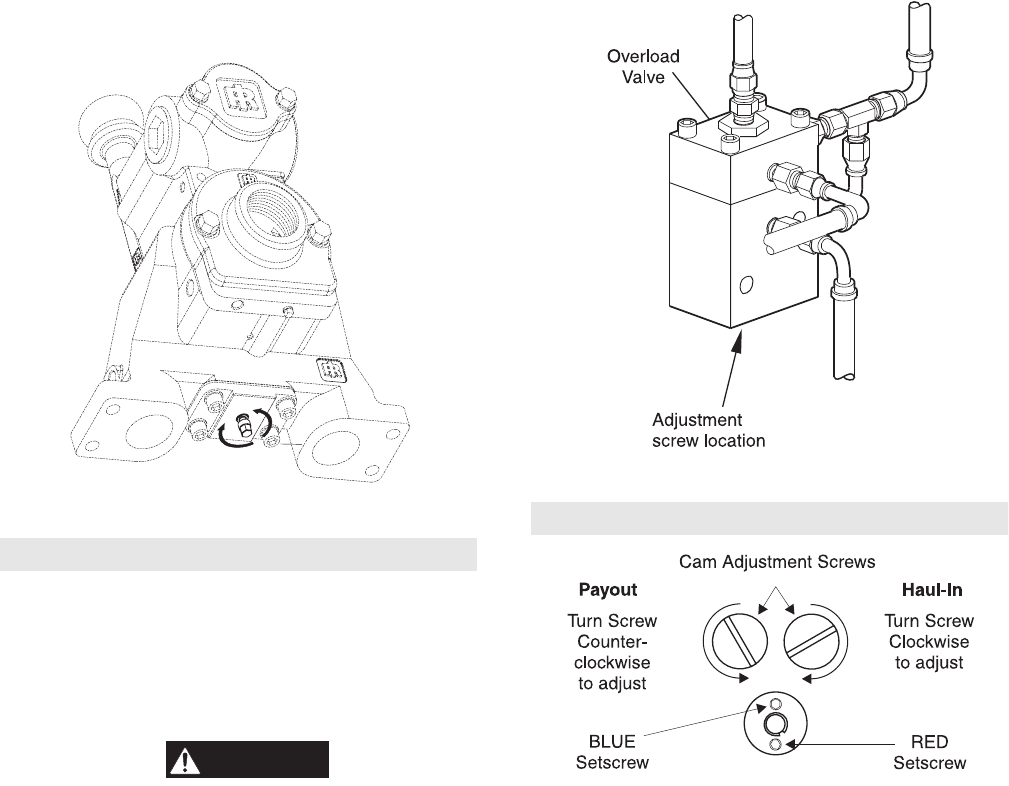

Overload Valve Adjustment (new style)

(Dwg. MHP2216)

Overload Valve Adjustment (optional feature)

old style

Refer to Dwg. MHP1678 on page 27.

Adjust overload valve by turning adjustment screw located at

bottom of valve.

Rotating screw clockwise will increase pressure required to

activate shutoff valve.

WARNING

• This adjustment can cause overload device to NOT activate

before winch’s safety limit is exceeded. This procedure should

only be done by personnel trained in testing and servicing this

winch.

Rotating adjustment screw counterclockwise will decrease

pressure required to activate shut off valve.

Checking Overload Valve Setting:

1. Attach load line to a load that is calibrated to 150% of the

maximum load for which winch is rated. Move control lever

to haul-in position. If winch lifts load, adjust screw as

described below.

Setting the Overload:

1. Attach load line to a load that is calibrated to 150% of winch

rated capacity.

2. When control lever is moved to haul-in position, overload

valve should activate shut off valve. Reset emergency stop

valve, valve is adjusted.

3. If winch lifts load, lower load. Turn adjustment screw

counterclockwise in ¼ turn increments until shut off valve is

activated. After each ¼ turn, retest winch.

Overload Valve Adjustment (old style)

(Dwg. MHP1678)

Limit Switch Adjustment (optional feature)

(Dwg. MHP0607)

To set winch maximum wire rope payout limit switch:

1. Remove access plate from top of limit switch.

2. Loosen blue setscrew in center of limit switch, below access

cover.

3. Position winch wire rope at desired payout position.

4. Rotate left cam adjustment screw counterclockwise until it

fully activates cutoff valve, causing system air to vent. 2¾

turns of the cam adjustment screw are required for each full

cam revolution.

5. Hold cam adjustment screw in position (venting air) and

tighten blue setscrew to lock cam in place.

6. If required, adjust haul-in limit switch. Test winch set points

by operating winch through three complete cycles to ensure

consistent limit switch operation within +/- 2 feet (2/3 metre)

of set points.

7. Install access cover when final adjustments are complete.

To set winch maximum wire rope haul-in limit switch:

1. Remove access plate from top of limit switch.

2. Loosen red setscrew in center of limit switch, below access

cover.

3. Position winch wire rope at desired switch activation

position.

4. Rotate right cam adjustment screw clockwise until it fully

activates cutoff valve, causing system air to vent. 2¾ turns of

cam adjustment screw are required for each full cam

revolution.