MHD56037 - Edition 5 23

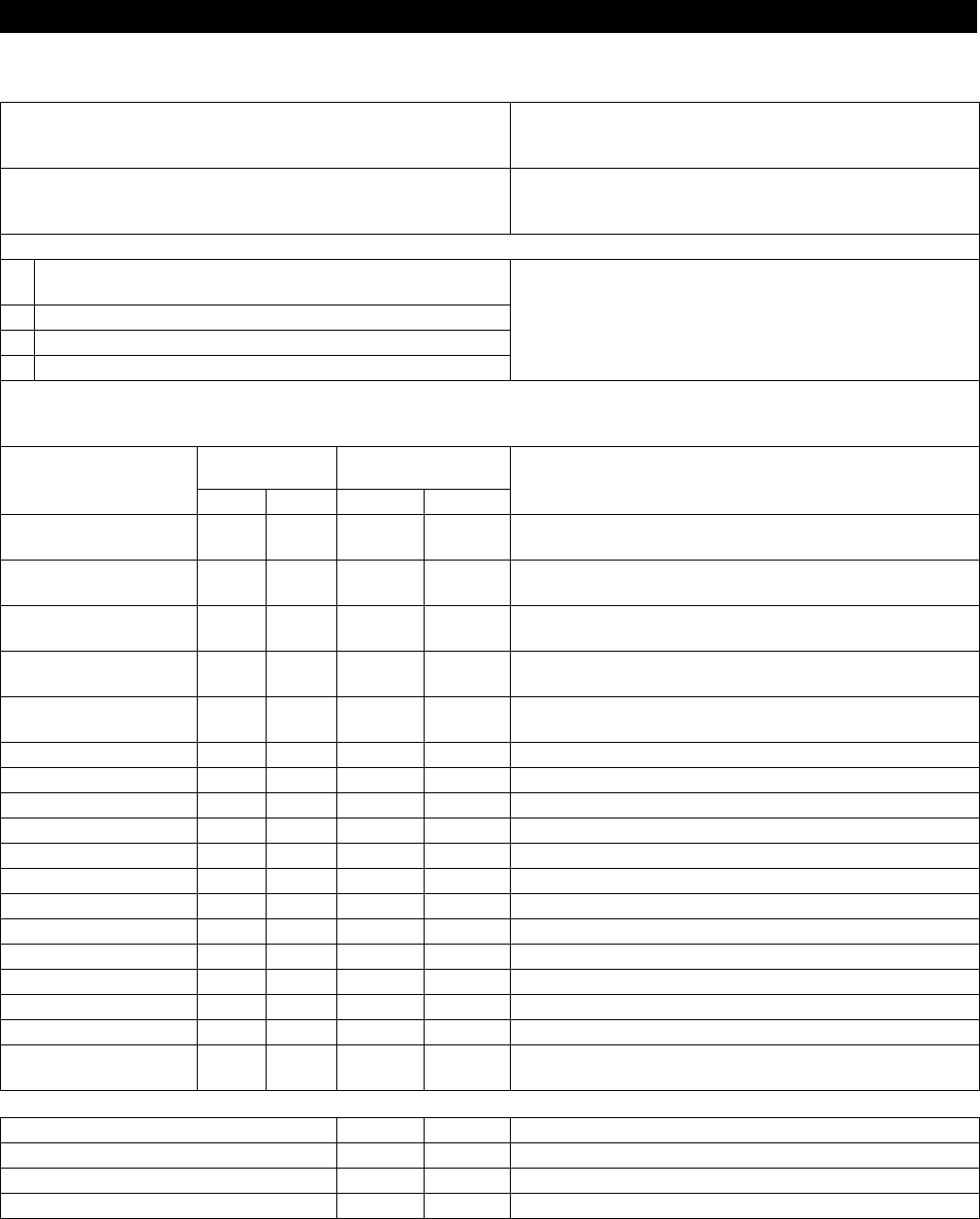

INSPECTION AND MAINTENANCE REPORT

Ingersoll-Rand Force 5 Series FA5 and FA5T Air Winches

Model Number: Date:

Serial Number: Inspected by:

Reason for Inspection: (Check Applicable Box)

1. Scheduled Periodic Inspection

(_____ Quarterly _____ Semiannually _____ Yearly) Operating Environment:

Normal ___ Heavy ___ Severe ___

2. Discrepancy(s) noted during Frequent Inspection

3. Discrepancy(s) noted during maintenance

4. Other: ___________________________

Refer to the Parts, Operation and Maintenance Manual “INSPECTION” section for general inspection criteria. Also, refer to appropriate

National Standards and Codes of practice. If in doubt about an existing condition, contact the nearest Ingersoll-Rand Distributor or the

factory for technical assistance.

COMPONENT

CONDITION

CORRECTIVE

ACTION

NOTES

Pass Fail Repair Replace

Uprights and

Side Rails

Drum Band Brake

(125% Load Test)

Disc Brake

(125% Load Test)

Drum Band Brake

(Visual Inspection)

Disc Brake

(Visual Inspection)

Motor

Limit Switches

Controls

Air System

Fasteners

Reduction Gears

Labels and Tags ---

Shafts

Wire Rope Wedge ---

Emergency Stop Valve ---

Overload Device ---

Wire Rope ---

Other Components

(list in NOTES section)

TESTING Pass Fail NOTES

Operational (No Load)

Operational (10% Load)

Operational (Maximum Test Load*)

* Maximum test load is 125% of rated line pull. Testing to more than 125% of rated load may be required to comply with standards and

regulations set forth in areas outside the USA.

This form may be copied and used as an inspection/maintenance record.