10 MHD56037 - Edition 5

Installing Wire Rope

CAUTION

• To avoid disc brake damage when installing wire rope

pressurize brake with a minimum of 60 psi (4.1 bar) air from

an auxiliary source.

Refer to Dwg. MHP0166 on page 10.

1. Cut wire rope to length in accordance with wire rope

manufacturer’s instructions.

2. Feed end of wire rope into wire rope anchor hole in drum

and pull through approximately one foot (305 mm) of wire

rope.

(Dwg. MHP0166)

3. Wrap wire rope with wire a distance from the end equal to

wedge length plus one inch (25 mm).

4. Slide sleeve over end of wire rope so larger diameter of taper

bore is nearest the end of wire rope.

5. Spread end strands of wire rope and insert split wedge until

it is below the end of wire rope.

6. Pull sleeve over wire rope end until tight. Check that wire

rope strands stay in the slots located on split wedge.

7. Pull wire rope anchor into position in drum anchor pocket.

CAUTION

• Make sure first wrap of wire rope is tight and lays flush

against drum flange.

Safe Wire Rope Handling Procedures

1. Always use gloves when handling wire rope.

2. Never use wire rope which is frayed or kinked.

3. Never use wire rope as a sling.

4. Always ensure wire rope is correctly spooled and the first

layer is tight against drum.

5. Always follow wire rope manufacturers’ recommendation on

use and maintenance of wire rope.

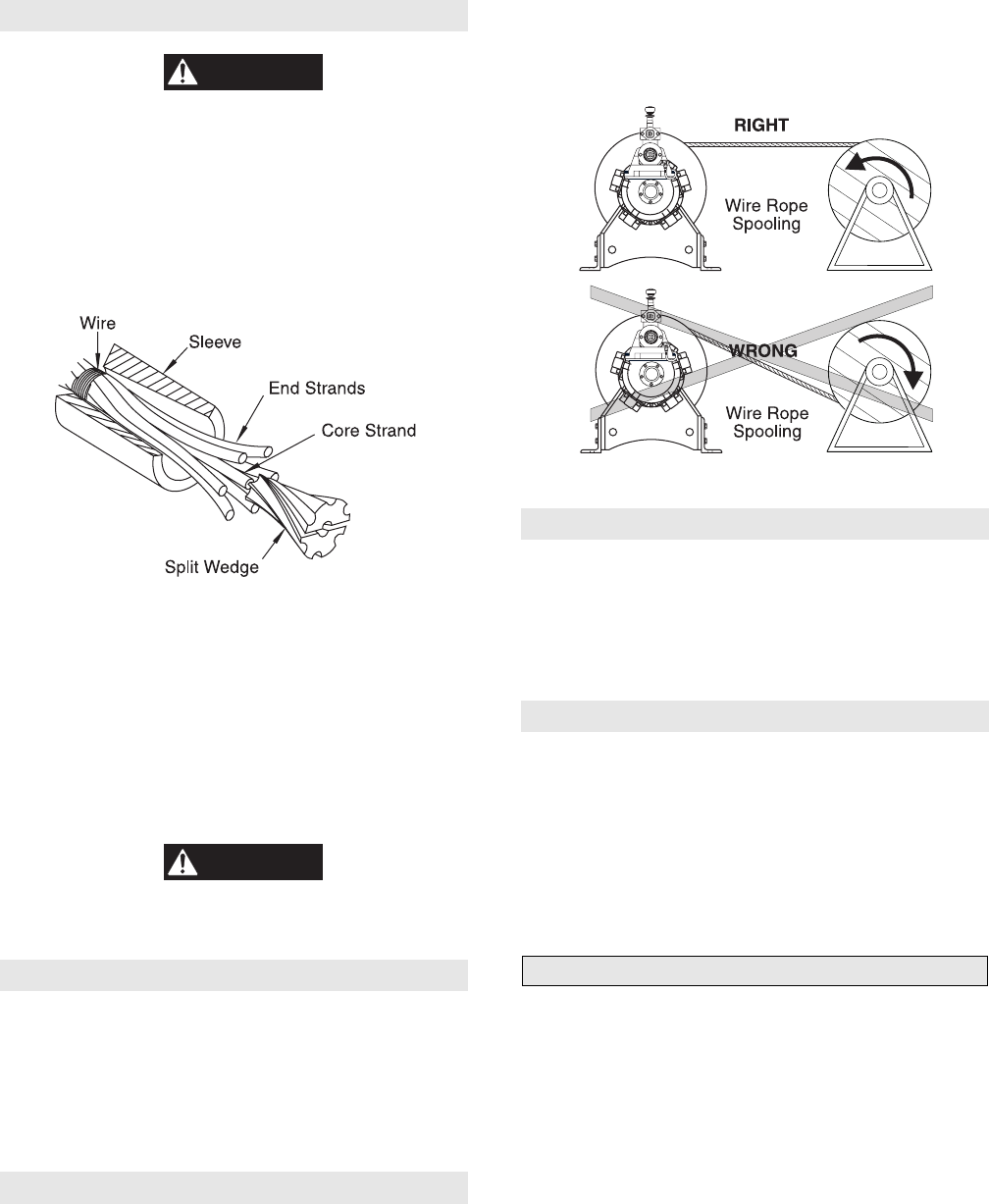

Wire Rope Spooling

Refer to Dwg. MHP2125 on page 10.

To compensate for uneven spooling and decrease in line pull

capacity as drum fills up, use as short a wire rope as practical.

When rewinding apply tension to the end of wire rope to eliminate

slack. This helps achieve level winding and tight spooling.

Support wire rope spool and have wire rope come off top of spool

and over top of winch drum. This will prevent damage to wire

rope.

Spooling Wire Rope onto Winch Drum

(Dwg. MHP2125)

Rigging

Make sure all wire rope blocks, tackle and fasteners have a

sufficient safety margin to handle required load under all

conditions. Do not allow wire rope to contact sharp edges or

make sharp bends which will cause damage to wire rope, use a

sheave. Refer to wire rope manufacturer’s handbook for proper

sizing, use and care of wire rope.

Safe Installation Procedures

1. Do not use wire rope as a ground (earth) for welding.

2. Do not attach a welding electrode to winch or wire rope.

3. Never run wire rope over a sharp edge. Use a correctly sized

sheave.

4. When a lead sheave is used, it must be aligned with center of

drum. The diameter of lead sheave must be at least 18 times

diameter of wire rope. Refer to Dwg. MHP2123

on page 9.

5. Always maintain at least three full, tight wraps of wire rope

on drum.

Air Supply

The air supply must be clean, free from moisture and lubricated to

ensure optimum motor performance. Foreign particles, moisture

and lack of lubrication are the primary causes of premature motor

wear and breakdown. Using an air filter, lubricator and moisture

separator will improve overall winch performance and reduce

unscheduled down time.

Air consumption for the FA5 and FA5T air motor is 700 scfm (20

cu. m/min.) at rated operating pressure of 90 psig (6.3 bar) at

winch motor inlet. If air supply varies from recommended, then

winch performance will change.