20 MHD56037 - Edition 5

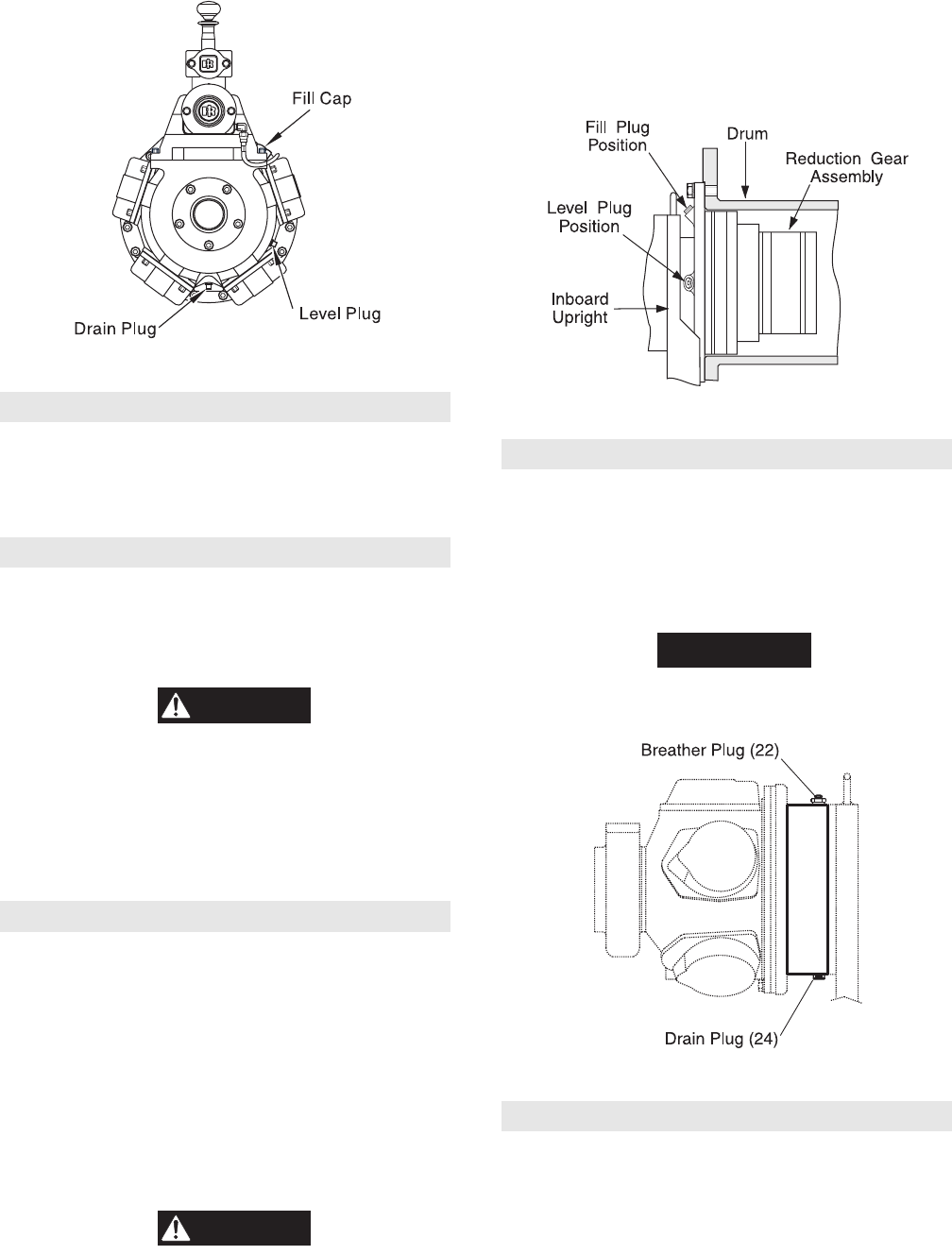

K5B Motor Lubrication Locations

(Dwg. MHP2126)

Air Throttle

Refer to Dwg. MHP0165 on page 54. Periodically, depending on

winch usage and severity of environment, lubricate lever air

throttle (local and remote) with recommended grease at grease

fitting (246).

Wire Rope

Follow wire rope manufacturer’s instructions. At a minimum,

observe the following guidelines.

1. Clean with a brush or steam to remove dirt, rock dust or other

foreign material on surface of wire rope.

CAUTION

• Do not use an acid-based solvent. Only use cleaning fluids

specified by wire rope manufacturer.

2. Apply Ingersoll Rand LUBRI-LINK-GREEN

or ISO VG

100 (SAE 30W) oil as a wire rope lubricant.

3. Brush, drip or spray lubricant weekly, or more frequently,

depending on severity of service.

Reduction Gear Assembly

Refer to Dwg. MHP0140 on page 20.

It is recommend that the first oil change be done after

approximately 50 hours initial operation. Always inspect removed

oil for evidence of internal damage (metal shavings, dirt, water,

etc.).

The reduction gear is filled to the correct levels prior to shipment

from the factory. Check oil level before initial winch operation.

This component is splash lubricated by oil in the housing and has

no other means of lubrication. It is therefore important to use high

quality Extreme Pressure (EP) rust and oxidation inhibited gear oil

to ensure maximum performance and minimum down time for

repair.

CAUTION

• Do not over fill. Excess oil will reduce operating efficiency

and increase oil temperature.

To ensure correct performance, highest efficiency and long life, it

is essential that lubricating oil be maintained at correct level.

Rotate drum until fill plug is located at top dead center then add

oil up to level plug hole. Oil capacity for reduction gear assembly

is 4 quarts (3.8 litres).

Reduction Gear Lubrication Plug Locations

(Dwg. MHP0140)

Disc Brake (optional feature)

Refer to Dwg. MHP1348 on page 20.

The friction plates and drive plates are in a self contained oil bath

and have no other means lubrication. After an oil change or winch

overhaul remove the breather plug (22) and pour a small amount

of oil [4 to 6 ounces (0.2 litres)] through breather hole in brake

housing. Allow oil to fully settle between fillings.

NOTICE

• If too much oil is added excess oil will be discharged through

breather plug when control valve is actuated.

(Dwg. MHP1348)

Seals and Bearings

If winch is disassembled, clean all parts thoroughly and coat

bearings and seals with clean grease. Refer to ‘Recommended

Lubricants’ section. Use sufficient grease to provide a good

protective coat. Lubricate grease fittings monthly with 2 or 3

pumps of a grease gun.