MHD56037 - Edition 5 11

Air Lines

Inside diameter of winch air supply lines must not be less than

sizes shown in Table 4

on page 11. Before making final

connections, all air supply lines should be purged with clean,

moisture free air or nitrogen before connecting to winch inlet.

Supply lines should be as short and straight as installation

conditions will permit. Long transmission lines and excessive use

of fittings, elbows, tees, globe valves etc. cause a reduction in

pressure due to restrictions and surface friction in lines.

Table 4–Minimum Allowable Air Supply Line Sizes

Air Line Lubricator

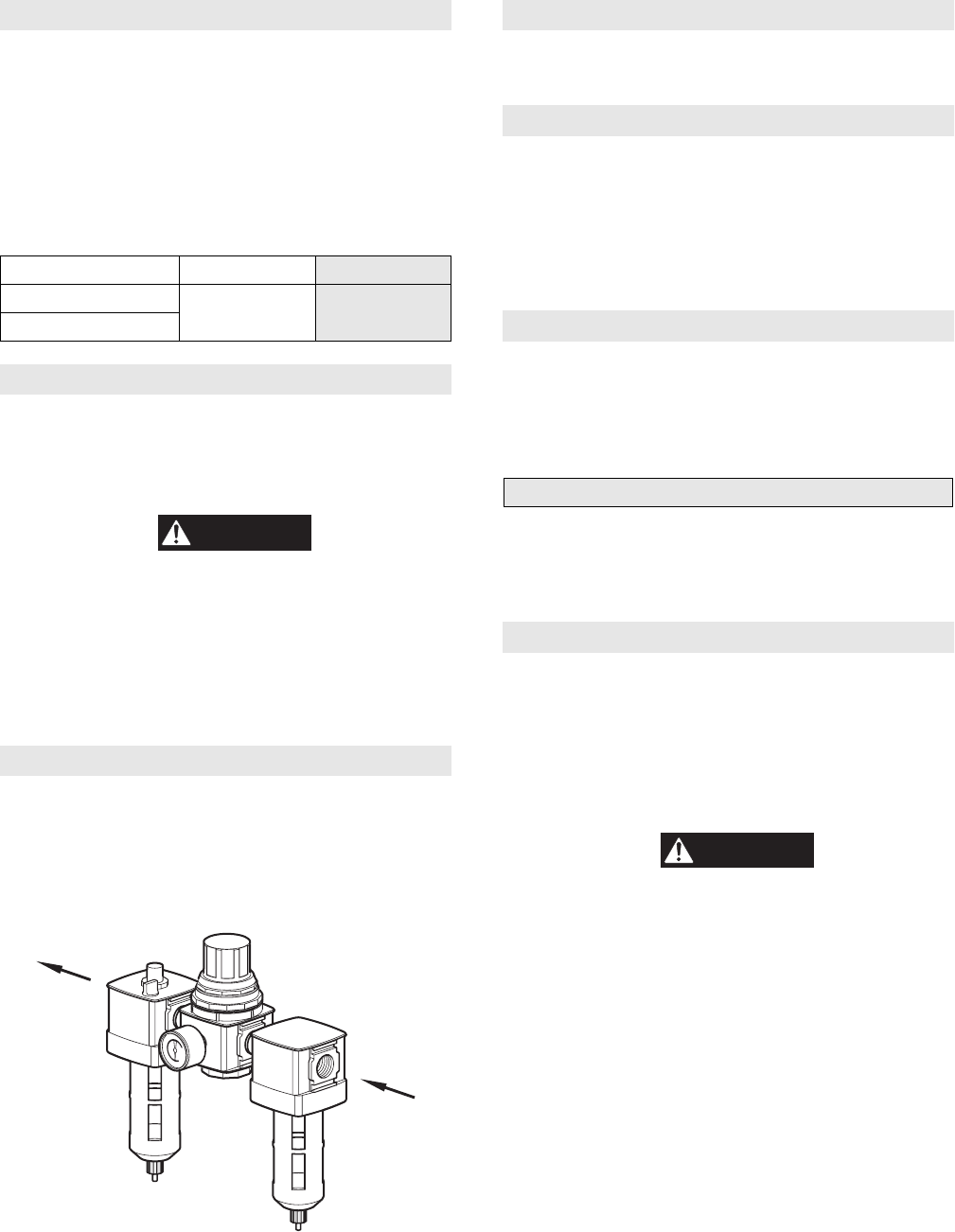

Refer to Dwg. MHP0191 on page 11.

Always use an air line lubricator with these motors. The lubricator

must have an inlet and outlet at least as large as inlet on motor.

Install air line lubricator as close to air inlet on motor as possible.

CAUTION

• Lubricator must be located no more than 10 ft. (3 m) from

motor.

• Shut off air supply before filling air line lubricator.

The air line lubricator should be replenished daily and set to

provide 6 to 9 drops per minute of ISO VG 32 (SAE 10W) oil. A

fine mist will be exhausted from throttle control valve when air

line lubricator is functioning properly.

Air Line Filter

Refer to Dwg. MHP0191 on page 11.

It is recommended that an air line strainer/filter be installed as

close as practical to motor air inlet port, but before lubricator, to

prevent dirt from entering valve and motor. The strainer/filter

should provide 20 micron filtration and include a moisture trap.

Clean the strainer/filter periodically to maintain its operating

efficiency.

(Dwg. MHP0191)

Air Pressure Regulator

If an air pressure regulator is used, install between lubricator and

filter. Refer to Dwg. MHP0191

on page 11.

Moisture in Air Lines

Moisture that reaches the air motor through air supply lines is a

primary factor in determining the length of time between service

overhauls. Moisture traps can help to eliminate moisture. Other

methods, such as an air receiver which collects moisture before it

reaches motor or an aftercooler at compressor that cools air to

condense and collect moisture prior to distribution through supply

lines are also helpful.

Mufflers

Make sure mufflers are installed in winch exhaust manifold and

control valve exhaust port. An additional muffler is used on

winches equipped with an emergency stop and overload device.

Check mufflers periodically to ensure they are functioning

correctly.

Motor

For optimum performance and maximum durability of parts,

provide an air supply of 90 psig at 700 scfm (6.3 bar/630 kPa at

20 cu. m/m) as measured at motor inlet. The air motor should be

installed as near as possible to compressor or air receiver.

Emergency Stop and Overload System (optional feature)

Refer to Dwg. MHP1492 on page 12.

old style

The air supply line is connected to the shutoff valve which is

connected to the air control valve. When Emergency Stop valve is

activated, a pilot signal is sent to the shut off pilot valve which

directs shutoff valve to cut off air to winch, immediately stopping

all winch movement.

CAUTION

• If winch continues to move (payout load) after shutoff valve

activates, brake(s) are not holding load and need to be

adjusted or repaired.

The overload system also activates shutoff valve. When Delta-P

valve senses a preset pressure difference between the two ports,

located on rotary housing, it directs a pilot signal to shutoff pilot

valve activating the shutoff valve. Refer to Dwg. MHP1491

on

page 12.

Model inch mm

FA5

1-1/2 38

FA5T

Air Out

Regulator

Lubricator

Air In

Filter