27

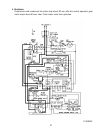

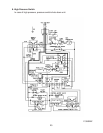

IV. Service Diagnosis

A. Diagnostic Procedure

This diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components under normal operating conditions of 70°F or warmer air and

50°F or warmer water temperatures. Before proceeding, check for correct installation,

proper voltage per unit nameplate and adequate water supply.

1) Unplug the unit from the electrical outlet and access the control panel.

2) Plug the unit back in. Make sure the ush switch is in the ICE position, then place the

power switch in the ON position.

3) Fill Cycle – The water valve energizes. The reservoir begins to ll and the lower oat

switch closes. Nothing occurs at this time. The reservoir continues to ll and the upper

oat switch closes, energizng the water control relay. When the water control relay

energizes, the inlet water valve de-energizes and the low water safety circuit closes to

the timer board. Diagnosis: Check that the water valve lls the reservoir. If not, check

for clogged water lters, clogged water valve screen, power supply to the unit, power

circuit to the water valve (power switch, high pressure switch, transformer, safety switch,

safety relay contacts, fuse, bin control, ush switch, ush relay, ush relay contacts, oat

switch, water control relay contacts), and the coil on the water valve.

3) Ice Purge Cycle – (short cycle protection) The gear motor and the gear motor protect

relay energize, and the 60 second compressor short cycle protection timer starts.

Diagnosis: Check that the gear motor starts. If not, check the low water safety circuit

on terminals 3 and 4 on the timer board, check for 120 volts on the gear motor relay

terminal 8 on the timer board, check the gear motor fuse, thermal protector, and gear

motor windings. If the gear motor starts but the auger does not turn: check the gear

motor coupling between the auger and the gear motor. If the compressor starts the

same time the gear motor starts: Check the compressor relay on the timer board (the

black relay on the timer board is the compressor relay).

4) Freeze Cycle – The compressor and fan motor energize, the gear motor, gear motor

protect relay, ush switch relay, and the water control relay remain energized. Ice

production begins 4 to 6 minutes after the compressor and fan motor start depending

on ambient and water conditions. Diagnosis: Check that the compressor and fan

motor are running. If not, check for 120 volts on the compressor relay terminal 4 on the

timer board (the black relay on the timer board is the compressor relay), check for 120

volts on the gear motor protect relay, check gear motor relay contacts 4 and 6, check

voltage on the compressor terminals, check the internal overload (motor protector), the

compressor capacitors, and voltage to the fan motor and fan capacitor.