11

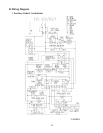

E. Sequence of Operation

Hoshizaki utilizes a solid state timer board to switch the components on and off as

needed. The sequence is as follows:

1. Startup

Flush switch in "ICE" position, power switch in "ON" position. FR energizes.

2. Fill Cycle

WV opens and the reservoir lls with water until UF/S closes. Note: GM will not start

unless UF/S is closed. For details, see "IV. Service Diagnosis".

3. Ice Purge Cycle (60 seconds)

WCR energizes, closing the low water safety circuit and de-energizing WV. GMR

energizes (clear relay located on TB). GM starts and GMPR energizes. GM runs for 60

seconds to clear any ice from the evaporator.

Note: Low water safety circuit is terminals 3 and 4 on TB.

4. Freeze Cycle (Ice Making Process)

CR energizes (black relay located on TB). Comp and FMS energize. As the water in the

evaporator cools, ice starts forming within 4 to 6 minutes. This time frame depends on

the inlet water and ambient temperature conditions.

UF/S and LF/S operate WV as needed to continue the ice making process. This

continues until BC shuts the ice maker down or power is turned off to the unit.

5. Shutdown:

BC activates (opens). FR de-energizes, FWV energizes. Approximately 90 seconds after

BC activates, Comp and FMS de-energize, one minute later GMPR de-energizes and

GM stops.

Legend: BC–bin control; Comp–compressor; CR–compressor relay; FMS–self-

contained fan motor; FR–ush relay; FWV–ush water valve; GM–gear motor;

GMPR–gear motor protect relay; GMR–gear motor relay; LF/S–lower oat

switch; TB–timer board; UF/S–upper oat switch; WCR–water control relay;

WV–inlet water valve.

F. Ice Production Check

To check production, prepare a bucket or pan to catch the ice and a set of scales to

weigh the ice. After the unit has operated for 10 to 20 minutes, catch the ice production

for 10 minutes. Weigh the ice to establish the batch weight. Multiply the batch weight by

144 for the total production in 24 hours.