8 GTO 4000XLS Instruction Manual © 01.10.12

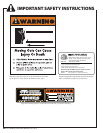

Step 5

Position the operator rear mount between post pivot bracket.

Place a

1

/2” bushing above the rear mount and a

3

/16” bushing

under the rear mount. Align the hole in rear mount, bushings

and post pivot bracket and secure with the 3

1

/2” clevis pin

and hair pin clip.

Step 6

Place a

3

/16” bushing under the front mount and attach the

gate bracket to the front mount using the 1

3

/4” clevis pin and

hairpin clip.

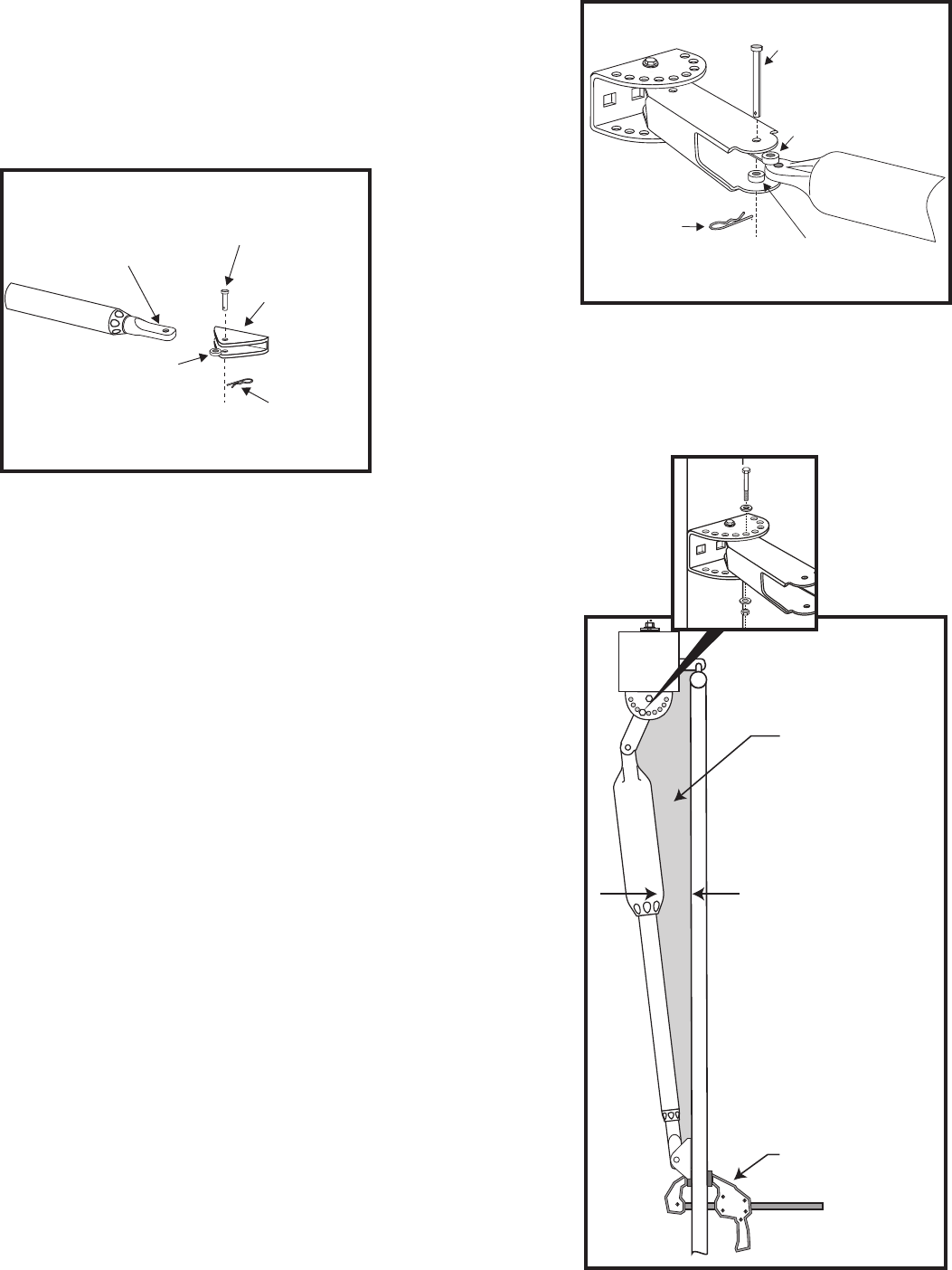

Check Clearance

Step 7

Open the gate to the desired open position. Position the

operator so that the gate bracket rests against the gate along

the level scribed line. Check the clearance between the

operator and the gate. The operator should only make contact

with the gate at the gate bracket. There should be a minimum

clearance of 2” between the widest part of the operator arm

and the gate.

When you have achieved the best position for the post pivot

bracket in the open position, insert the

3

/8” x 3

3

/4” bolt and

3

/8”atwasherthroughthealignedholesofthepostbracket

and post pivot bracket to hold it in place.

Clamp the gate bracket to the gate using c-clamps or another

type of clamp.

IMPORTANT: While determining the position of the post

pivot bracket, be sure that the position allows for minimum

2“ of clearance between the gate and the operator in both

the open and closed positions. This clearance will give the

operator the most ecient leverage point for opening and

closing the gate and, more importantly, provides the least

possible pinch area.

Operator

3/8” x 3-1/2” Clevis Pin

3/8” x 1/2” Delrin Bushing

3/8” x 3/16” Delrin Bushing

under rear mount

Hairpin Clip

3/8” x 1-3/4” Clevis Pin

Hairpin Clip

Gate Bracket

Front Mount

3/8” x 3/16” Delrin Bushing

under front mount

Clamp

Gate in the

OPEN POSITION

Pinch Area

2" minimum