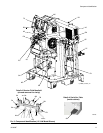

Spray Adjustments

16 313539F

Cycle Count Key/LED

Press to display cycle count.

NOTE:

To clear counter, press and hold for 3 sec.

Hydraulic Pressure Control

Knob

Use to adjust hydraulic pressure available to the hydrau-

lic drive system. Turn knob (HC) clockwise to increase

pressure and counterclockwise to decrease pressure.

Use hydraulic pressure gauge (HP, page 11) to view

hydraulic pressure.

NOTE:

Component A and B outlet pressures will be higher than

the hydraulic set pressure, depending on the model.

Component A and B pressure may be viewed on the

pressure gauges (GA, GB), or the higher of the two

pressures may be displayed on the motor control panel

(MC). See F

IG. 3, page 11.

Motor Control Arrow Keys

Use or to:

• Adjust pressure imbalance settings, page 26.

• Adjust standby settings, page 30.

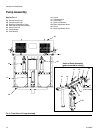

Spray Adjustments

Flow rate, atomization, and amount of overspray are

affected by four variables.

• Fluid pressure setting. Too little pressure results in

an uneven pattern, coarse droplet size, low flow,

and poor mixing. Too much pressure results in

excessive overspray, high flow rates, difficult control,

and excessive wear.

• Fluid temperature. Similar effects to fluid pressure

setting. The A and B temperatures can be offset to

help balance the fluid pressure.

• Mix chamber size. Choice of mix chamber is based

on desired flow rate, fluid viscosity, and selected

ratio.

• Clean-off air adjustment. Too little clean-off air

results in droplets building up on the front of the

nozzle, and no pattern containment to control over-

spray. Too much clean-off air results in air-assisted

atomization and excessive overspray.

+-

ti7731a ti7732a