6050-065-L-11-08

13

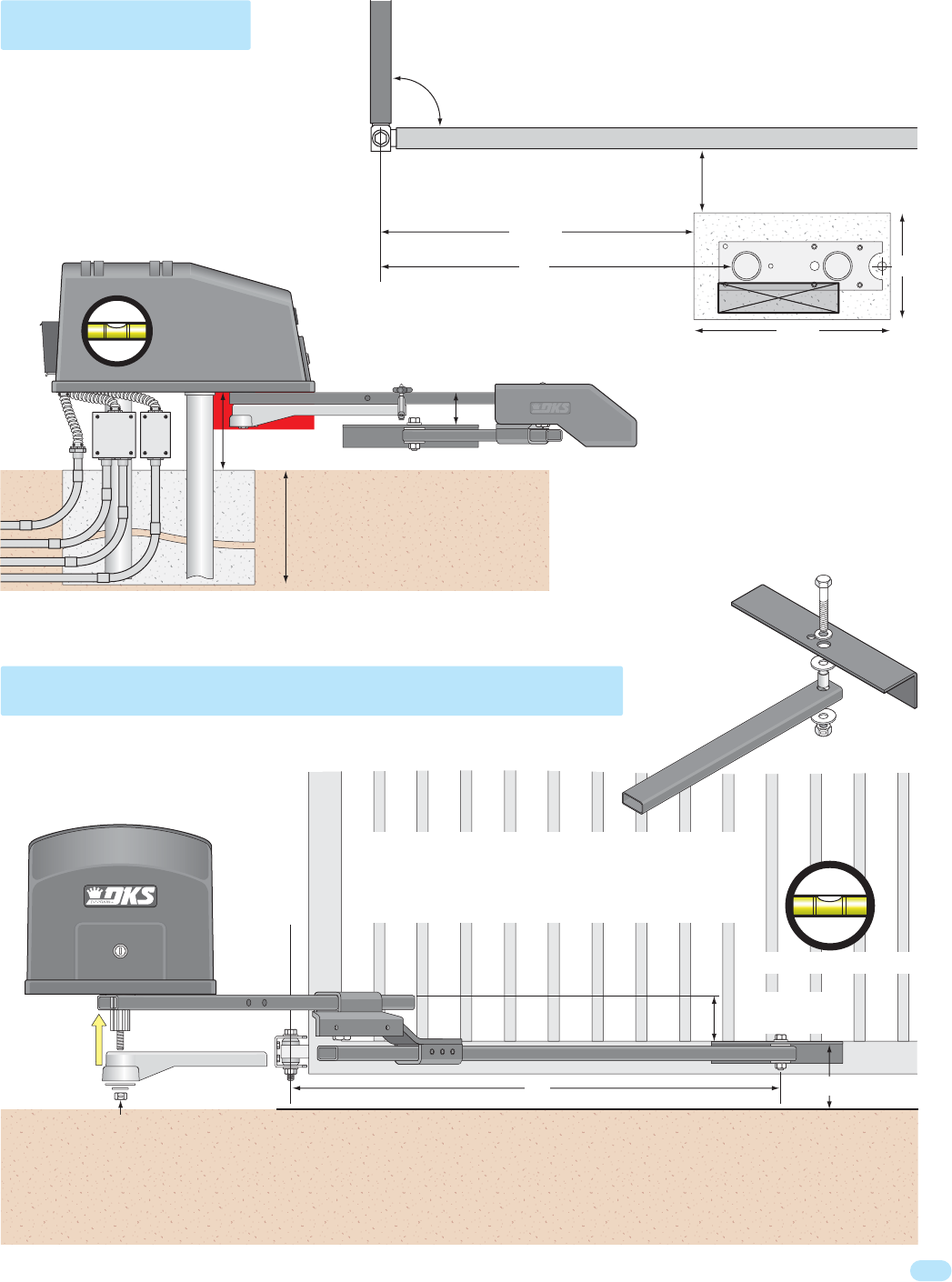

Arm

Rotation Area

Closed Gate

3”

1.5 Post Mount

1.6 Arm and Gate Bracket Installation

10”

18.5”

34”

6”

Do not insert the locking pin or padlock

into the crank arm. It will be installed

after arms have been adjusted.

Do not secure the elbow assembly

to the arms until the arms have

been adjusted. (See next page).

Mount the post base into the concrete

before installing the operator.

The post mount installation will allow

the operator to be mounted low enough

to attach the gate bracket to the lower

gate rail if desired.

Adjust the locknut on the crank power

arm so that it is snug against the

washer, but will still allow the crank arm

to rotate with little force. This is the

operator’s manual release option when

the crank arm is unlocked.

Assemble arms as shown with the gate in the closed

position. The elbow assembly’s flange MUST be on the

opposite side of the gate in the closed position. This is

the physical stop used to set the open and close limits.

Concrete

Position

Gate Rail

These measurements will work for standard or

convenience open models from 1.1 layout on page 10 ONLY.

Run all conduit on the opposite

side of the open gate.

Install gate

bracket to gate.

30” Crank Arm

60” Connecting Arm

Flange

Crank Power Arm

Elbow

Assembly

Top of Crank Arm

Point arms towards

gate bracket.

Gate Hinge Pivot Point

Arms MUST be level.

This distance can vary (6” minimum).

Varies

60” C

onnecting Arm

G

a

te

Bracket

Note: 2” thick gate Illustrated.

25.25”

Conduit

29”

Post Base

Open Gate

Closed Gate

90°

Depth of the concrete pad is

determined by soil conditions and

local building codes. Reinforced

concrete recommended.

Gate Bracket Height

3”

Low

Volt

High

Volt

Interconnection

Cable

Operator MUST

be level.