6050-065-L-11-08

29

• NO AC power Available.

• NO DC power.

• NO AC power.

• NO DC power.

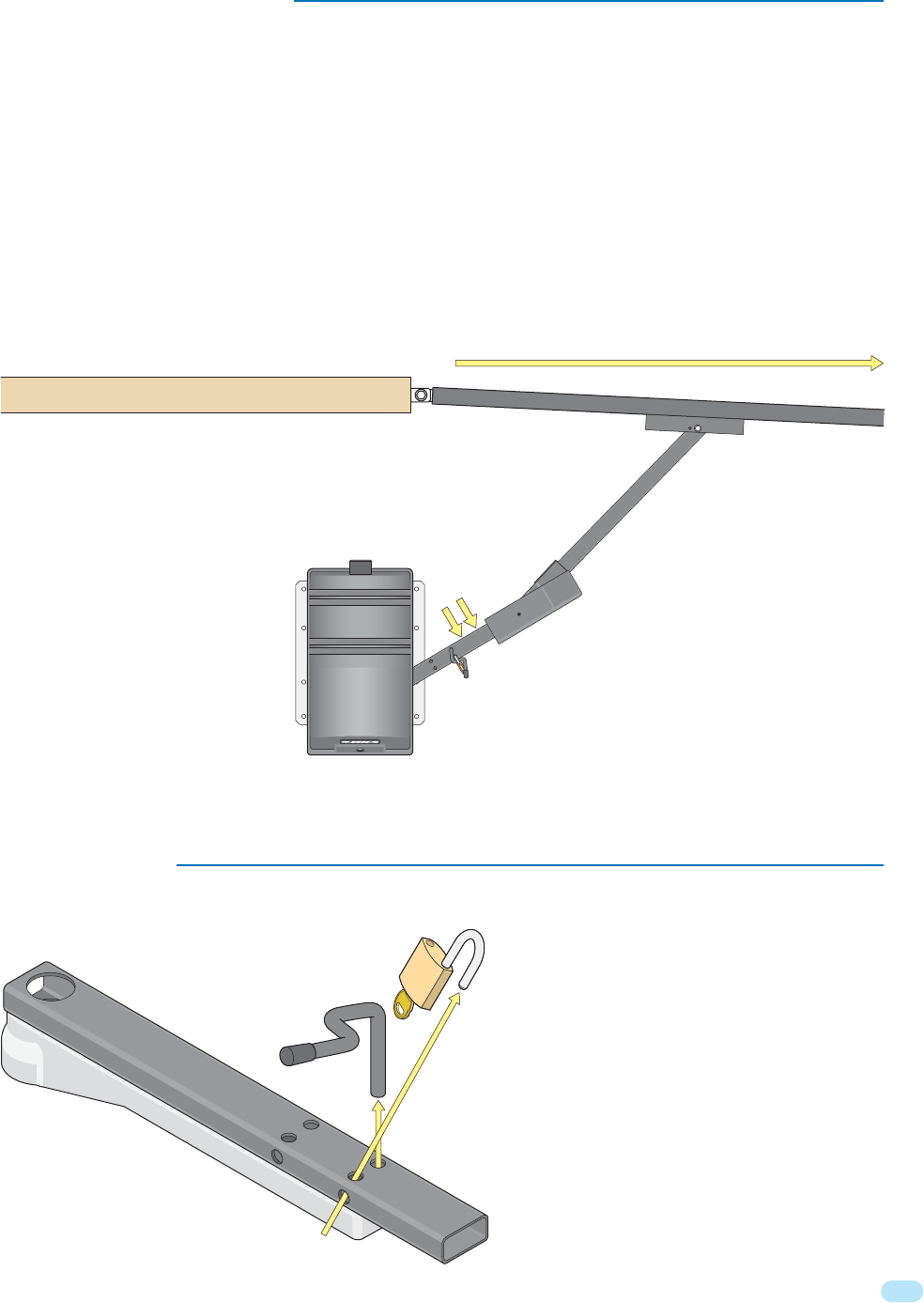

Pull Crank Arm

Fail-Safe Manual Operation

Manual Release

The FAIL-SAFE manual operation system is the most reliable and safest method for placing an automated gate in

manual operation and is the preferred method of emergency gate operation under worse case conditions by many Fire

Chiefs and Building Inspectors and is typically used in CLASS I and CLASS II applications. This system requires no

keys, cranks or tools for manual gate operation and is completely automatic. This prevents any delays for emergency

vehicle access in the event that a power outage has occurred.

In addition to FAIL-SAFE manual operation, this operator also employs a locked release pin to place the gate in manual

operation when primary (AC) power is removed.

• When AC power is removed (power failure or switch power off), the operator "FAILS" in a "SAFE" condition

allowing the gate to be manually pushed open without the need of any tools, keys, cranks or other devices.

This assures emergency vehicle access under the worst-case conditions.

•

For manual fail-safe gate operation, turn power to the operator OFF. If a backup power system is in

use, be sure that this power is turned OFF also. Once power is OFF, the gate can be manually operated.

To Manually Release Arm, turn AC power to the

operator OFF. If a backup power system is used, be sure

that this DC power is turned OFF also.

Remove padlock and locking pin from crank arm and

gate can be manually operated. Crank Power Arm will

remain stationary during gate movement.

Note: If an attempt is made to

force the gate open under normal

operating conditions (AC power

present), a tamper protect circuit

will detect the forced entry and

will start the motor to return the

gate to the closed position. If

Gate Tracker reporting is in use, a

forced entry attempt transaction

will be sent to the DoorKing

access control system at this

time.

1. Pull the gate crank arm (arm that is attached to the operator shaft) away from

the gate so the arms are not in a straight line.

2. Go to the end of the gate and pull it open.

Cra

nk Power Arm

Crank

Arm