8 9

1

CARE AND CLEANING

CAUTION: Always unplug the 3M™Attest™ Auto‑reader490 and allow to cool

before cleaning.

Do not spill liquid onto or into the instrument. Do not immerse the unit inliquid.

Clean external surfaces using only the instructions provided by themanufacturer.

The instrument must be returned to the manufacturer forrepair.

Clean the exterior surface of the 3M™Attest™ Auto‑reader490 by wiping it with a damp

cloth moistened with a mild detergent. Do not attempt to clean interior components. If

additional cleaning of the wells is required, call for repair orreplacement.

Note: The 3M™Attest™ Auto‑reader490 does not contain any user serviceable parts

or require any routine maintenance. Any malfunctions will be indicated by an error code.

Refer to the Troubleshooting Guide section for error codeexplanations.

TROUBLESHOOTING GUIDE

In the event of an error code, unplug the 3M™Attest™ Auto‑reader490 and plug it back in to initiate the self‑diagnostic test. If error code re‑occurs, call for repair orreplacement.

The LCD Display panel will indicate detected malfunctions by displaying a caution or error code under affected BI wells. The audible alarm, if active, sounds and the LCD Display

backlight flashes to alert the user to all caution (except C1) and error codes. The alarm and backlight can be silenced and extinguished, respectively, by pressing the Buzzer Alarm OFF

button

. Note that disabling the audible alarm does not disable the flashing LCD Display backlight. Refer to the following:

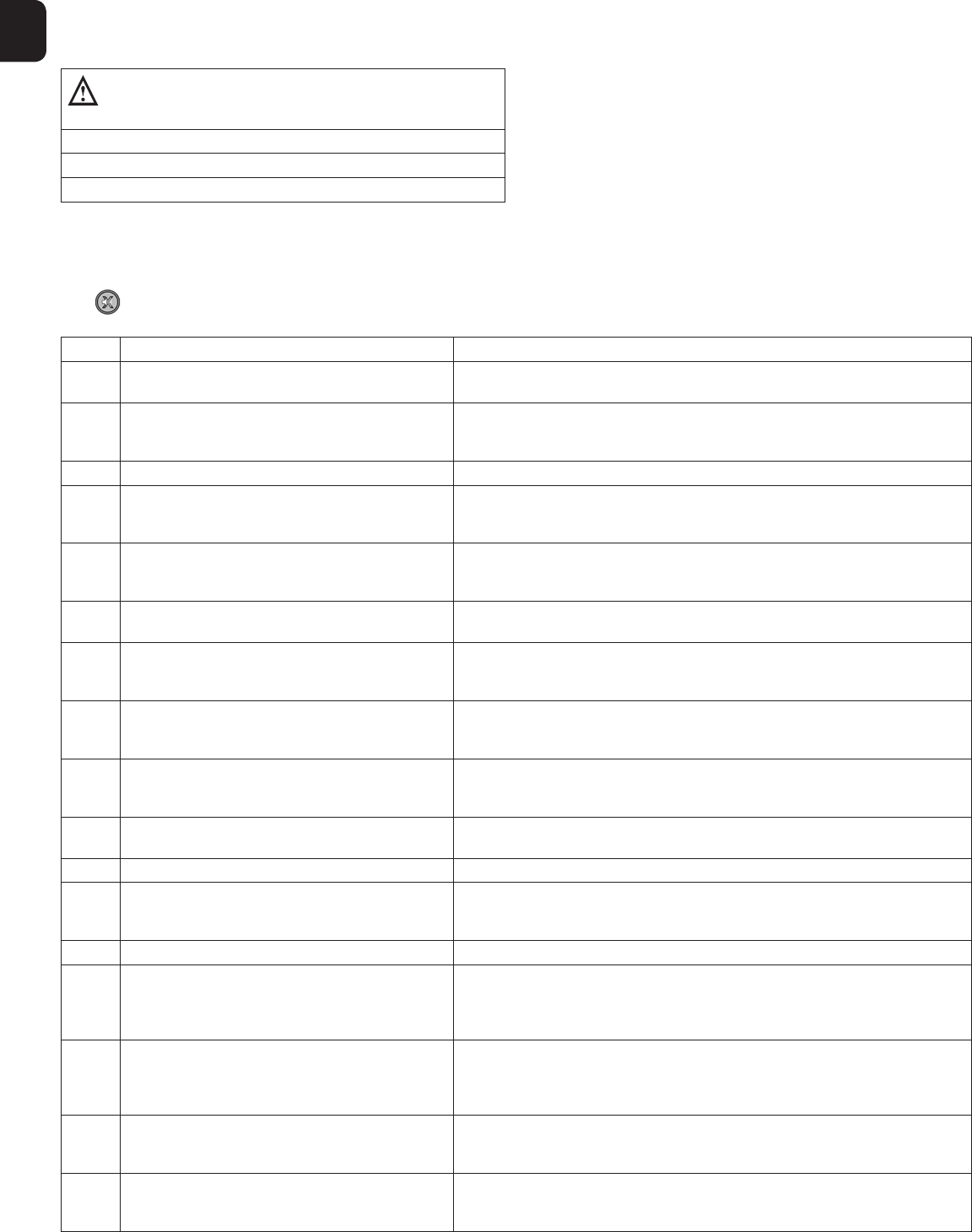

Code Problem Solution

C1 Unit Warm‑up Caution

Incubation block not attemperature.

Allow a 30 minute warm‑up after 3M™Attest™ Auto‑reader490 is plugged in. (Note: 3M™Attest™

Super Rapid Readout BI readings are disabled until incubator block reaches 56.5ºC+/‑2ºC).

C2 BI Removed from Well Caution

3M™Attest™ Super Rapid Readout BI has been removed

before incubation iscomplete.

Replace 3M™Attest™ Super Rapid Readout BI in proper well within 10 seconds to prevent loss of

collecteddata.

C4 Ambient Light Caution Move 3M™Attest™ Auto‑reader490 to reduced ambient lightconditions.

E1 Temperature Control Error

This error will occur if system is no longer able to control the

temperature of the incubator block (56.5ºC +/‑2ºC).

Cycle power to clearerror.

If error doesn’t clear, call for repair orreplacement.

E3 Memory Error

3M™Attest™ Auto‑reader490 unable to save/read data

frommemory.

Cycle power to clearerror.

If error doesn’t clear, call for repair orreplacement.

E7 Communications Error

This error will occur if internal communications havefailed.

Call for repair orreplacement.

E8 LED Error

This error occurs for a specific well if the system detects that a

UV LED or Optics Detection circuit is notworking.

Cycle power to clearerror.

If error doesn’t clear, call for repair or replacement. Do not use affected incubationwell.

E11 BI Inserted Incorrectly Error

Incubation time remaining will not display and fluorescent

readings are nottaken.

Remove BI and inspect to verify cap is closed, glass ampoule is crushed, and growth media is in

growth chamber. If necessary, repeat CLOSE, CRUSH, VERIFY, AND FLICK steps to properly activate BI

and return BI to well, ensuring it is seatedproperly.

E12 Power Failure Error

Power to Auto‑reader was off for too long to provide valid result

for affected BI(s).

Ensure power supply connection to Auto‑reader issecure.

E14 Ambient Light Error (occupied well)

Fluorescent result will notdisplay.

Rely on optional visual pH color change result for BI in affected well. Move 3M™Attest™

Auto‑reader490 to reduced ambient light conditions to avoid futureoccurrences.

Other Unwanted alarm sounds when positive BIdetected. Disable alarm, refer to 3M™Attest™ Auto‑reader490 Configuration section forinstructions.

Other Alarm Sounds

3M™Attest™ Super Rapid Readout Biological Indicator has

been removed from incubation/reader wellprematurely.

Replace 3M™Attest™ Super Rapid Readout Biological Indicator in incubation/reader well within

10seconds to prevent loss of datacollected.

Other LCD Panel does not displayproperly. Cycle power. If problem persists call for repair orreplacement.

Other Negative Control Vial

BI not properly activated. Media did not contact sporecarrier.

Control vial wassterilized.

Ensure BI cap is closed and glass ampoule iscrushed.

Flick BI until media flows to spore chamber at bottom ofBI.

Use a non‑sterilized vial as acontrol.

Check process indicator on BIcap.

Other Unexplained Positive BI

Adhesive residue onvial.

Test vial is absorbing fluorescent residue from a chemical

indicator ortape.

Do not place tape or labels onvial.

Place the vial so it does not come in direct contact with chemical indicators ortape.

Other 3M™Attest™ Auto‑reader490 will not enter Configuration

mode. Pushbutton Configuration may be disabled on

3M™Attest™ Auto‑reader490 WebApp.

On 3M™Attest™ Auto‑reader490 Web App Configuration Page, go to Pushbutton Configuration and

select the Enable radio button. Save changes to begin using newsetting.

Other 3M™Attest™ Auto‑reader490 LCD display flashes and

asterisks (***) and/or E11 and/or C4 codes appear on display

below unoccupied incubationwells.

Move 3M™Attest™ Auto‑reader490 away from sunlight or sources of incandescentlight.