Teledyne API Model T201 NH

3

Analyzer Operator Manual Maintenance Schedule

07271B DCN6646 31

18. After the Auto-Tune process is completed, verify that the “process”

temperature is indicating that the desired temperature is stable and

being regulated.

The converter is now ready for operation.

4.4 AUTOZERO FLOW CHECK

Since the T201 is an ammonia analyzer, the flow through the AutoZero

orifice is especially important. Check the AutoZero flow as follows:

1. This procedure should be performed with the sample pump running.

2. Remove the top cover of the analyzer. Locate the vacuum manifold at

the center rear of the chassis. Locate the 1/8” tube fitting located on

the very left side, as viewed from the rear of the analyzer. It will have a

label of “0.010” indicating the flow orifice installed.

3. Remove the fitting and attach a calibrated flowmeter to the block fitting

capable of measuring in the range of 500 cc/min. The flowmeter

should indicate a flow of 500 cc/min 10%.

4. If the flow is outside this range (most likely lower, due to plugging):

1. Turn off the sample pump and instrument.

2. Remove the 1/8” pipe-to-tube fitting and remove the ¼” sintered filter

(p/n FL0000001). This filter is meant to protect the orifice; it will

usually become plugged and need replacement rather than the

orifice. Replace the filter, and then re-assemble the manifold.

Restart the sample pump and recheck the flow.

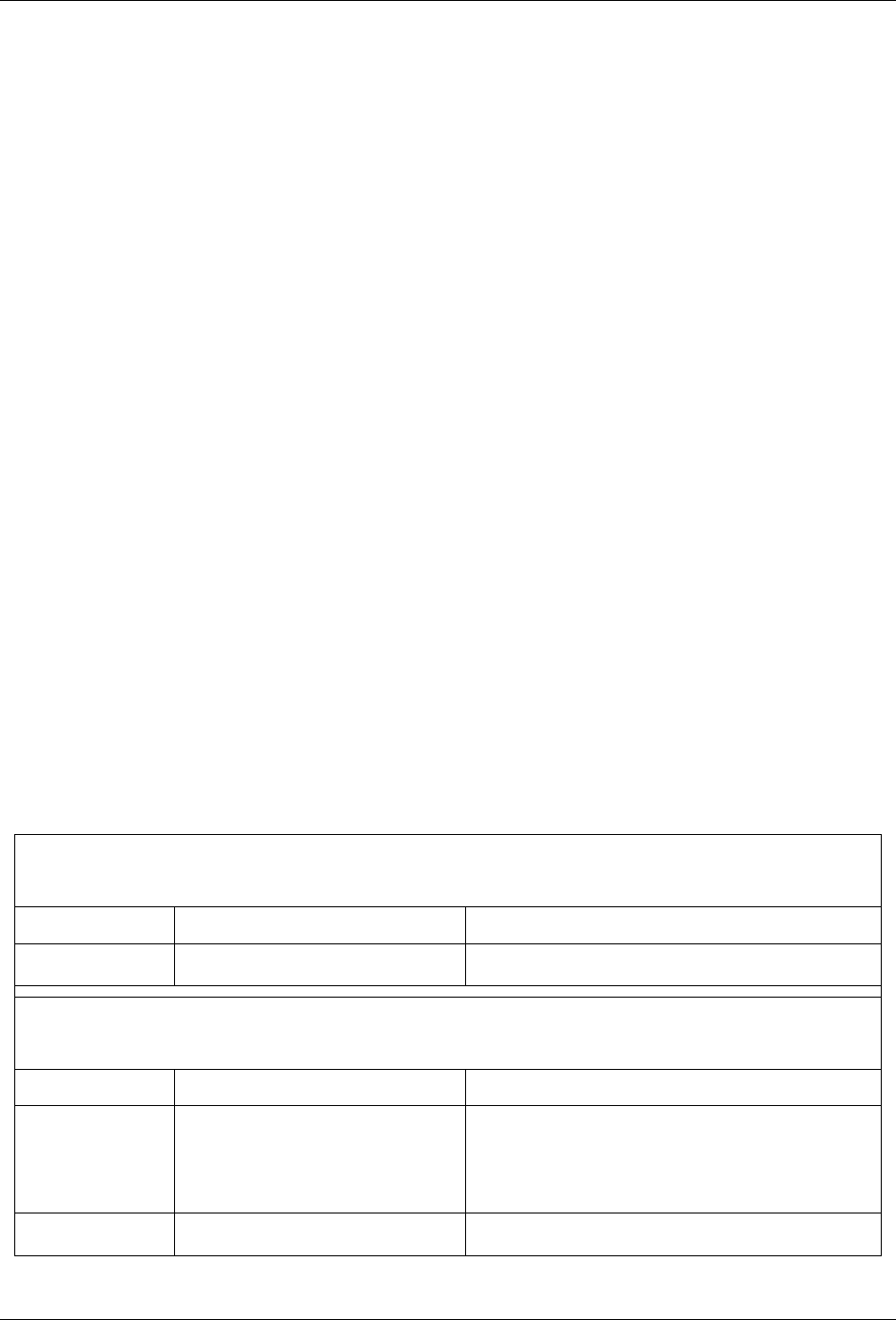

Table 4-3. Flow Check

M501

NH

3

CONVERTER SAMPLE FLOW CHECK

Note: Connect both the Teflon

tubes between analyzer and converter.

Gas Port Expected Flow (cc/min)

“SAMPLE IN” 1000 +/- 10 %

ANALYZER SAMPLE FLOW CHECK

Note: Disconnect both the Teflon

tubes between analyzer and converter.

Gas Port Expected Flow (cc/min)

“TO CONV”

1000 or 500, +/- 10 % When the analyzer is sampling TNx only, the

bypass flow is measured. Therefore, the flow

alternates between 500 and 1000 cc/min. This

is the NOx channel.

“FROM CONV” 500 +/- 10% This is the TNx channel.