4

Turn power switch off before conducting any maintenance procedures.

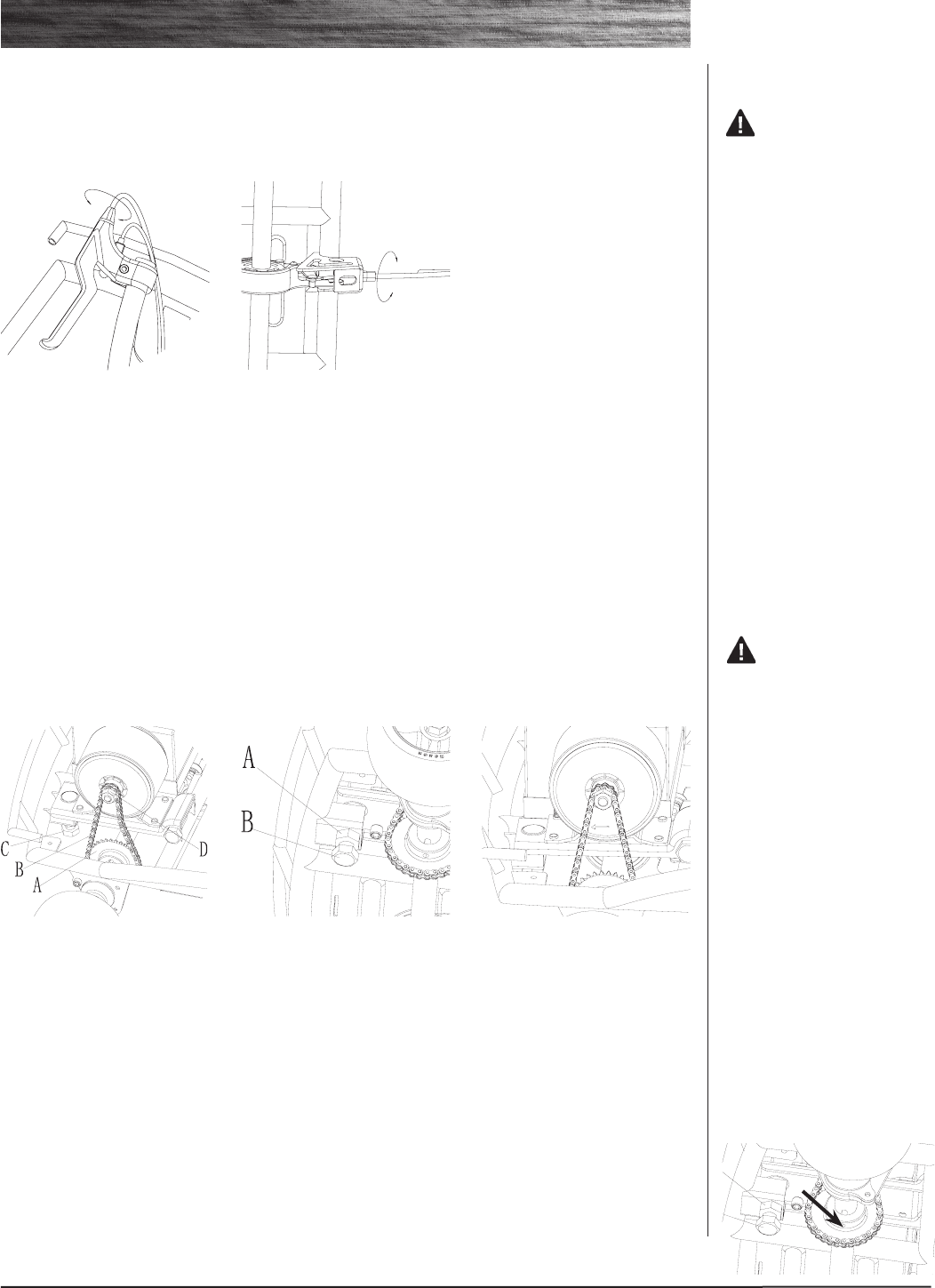

1 Using a 16mm open wrench,

loosen the chain jack-screw locknut

(B) and tighten or loosen the adjust-

ing bolt (A) to tighten or loosen the

chain as needed.

Note about chain adjustment:

The chain should not be under

tension nor floppy loose. There

should be about 3/8-inch (10mm)

of slack. BE CAREFUL NOT TO

ADJUST TOO TIGHT. The tensioning

system can easily impart too much

tension and snap the chain or bend

the motor output shaft. Turn the

adjusting bolt by hand 1/8 to 1/4

turn or less at a time and recheck

the adjustment each time.

2 Once the adjustment is good,

while holding the adjusting bolt,

retighten the locknut securely. Test

ride the Ground Force and readjust

as needed.

Note: If the locknut is not tightened

properly, the adjustment will vibrate

loose from normal use.

1 To adjust the brake, thread the

adjuster in or out 1/4 to 1/2 turns

until the desired brake adjustment

is attained.

The brake lever is fitted with a cable adjuster to compensate for cable stretch and/or to fine tune the lever movement

to brake engagement.

The chain drive system consists

of the drive-shaft sprocket (A), the

chain (B), the adjusting bolt (C), the

motor sprocket (D).

2 If the adjuster is threaded outward

and the brake still has too much slack,

use the auxiliary adjuster at the rear

brake for additional adjustments.

Note: When properly adjusted, the brake

lever will have approximately 3mm of

free play before the brake engages.

Need Help? Visit our web site for replacement parts, product support and a list of authorized service centers

at www.razor.com or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

ASSEMBLY AND SET-UP

q Adjusting Chain Tension

q Adjusting the Brake

WARNING: To avoid a

pinch or injury, keep fingers away

from moving sprockets and chain.

Note: The motor cover does

not need to removed for this

adjustment procedure. The chain

adjustment can be checked by

tipping the Ground Force on it’s side

and reaching under the cover (with

power switched OFF). However,

for the first time you make this

adjustment we recommend you

remove the cover to see exactly

what is happening.

Note: Proper alignment of the chain

must be maintained. If the chain

is adjusted properly, but is noisy

or rough running, check alignment

of the sprockets. The drive-shaft

sprocket can be adjusted slightly

from side-to-side by loosening

the set screw. Note that a key

maintains the drive position to the

shaft.

WARNING: Practice in

an open area free from obstacles

until you are familiar with the brake

function. DO NOT RUN OVER ANY

OBJECT AS IT COULD DAMAGE

THE BRAKE OR DRIVETRAIN.

If the drive system makes loud noises, slips or makes grinding sounds while turned on, this indicates the drive chain is

probably making the noise. This can be caused by the chain being adjusted too tight during assembly or coming loose

from normal wear-and-tear.