GTO 4000XLS Instruction Manual © 01.10.12 9

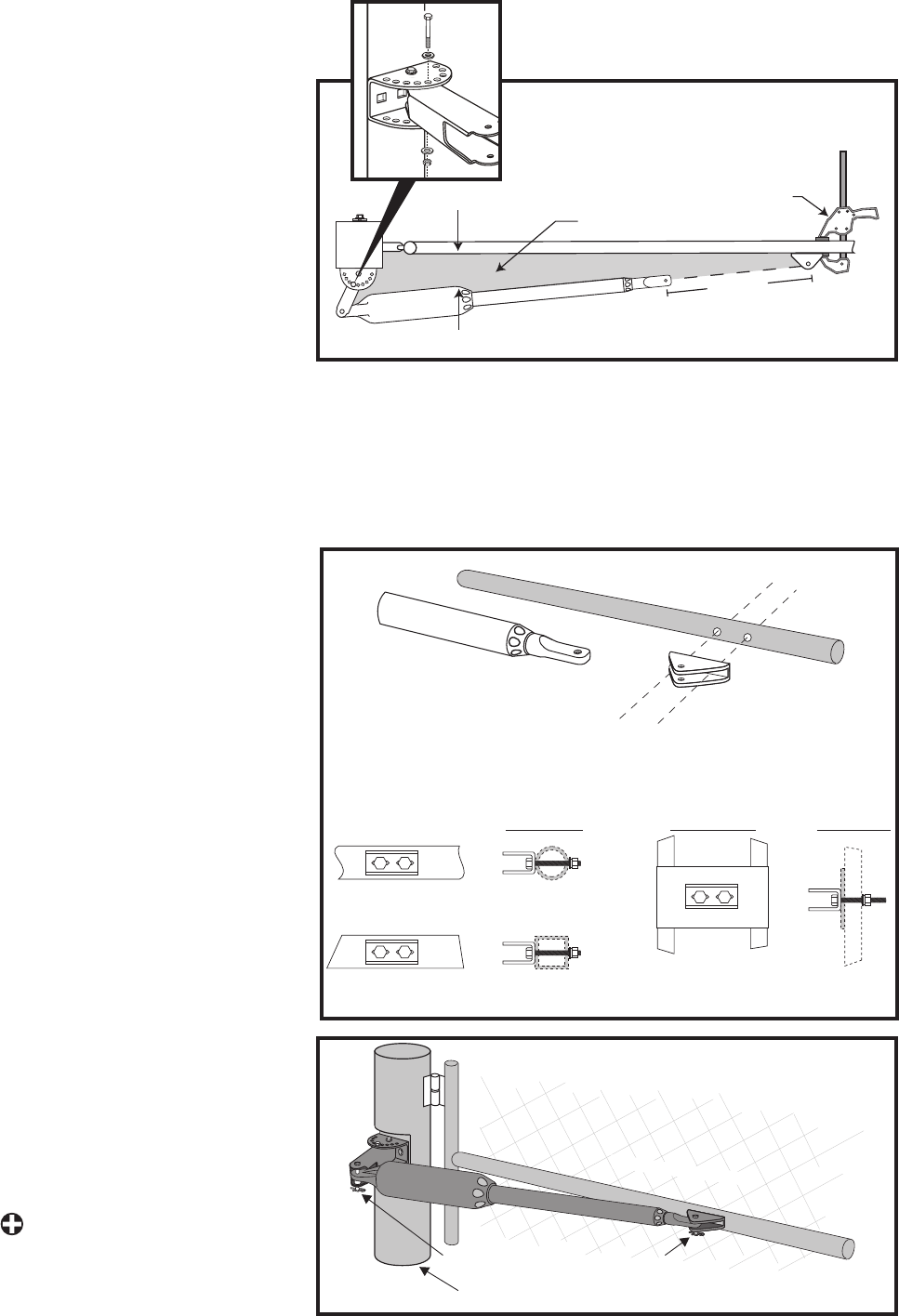

Gate in the

CLOSED POSITION

Pinch Area

2" minimum

MAX 22"

Clamp

Level Operator

Fence Post

Clevis Pin, Bushing, and Hairpin Clip

Gate In Open Position

LEVEL horizontal cross member

Mark cross member through middle of

gate bracket slots and drill 1/2" holes

Round Tube & Chain Link Gate

Square Tube Gate

Mounting Plate Created

for Decorative Gate

(required but not supplied)

FRONT VIEW

SIDE VIEW

FRONT VIEW

SIDE VIEW

Step 8

Remove the clevis pin from the front

mount and while supporting the gate

operator, swing the gate and gate

operator to the closed position. With

the gate and gate operator in the closed

position check the clearance and be sure

that the gate operator is not binding at

the post pivot bracket.

Ifyoudon’thave2”clearanceorthe

gate operator is binding on the post

pivot bracket, remove the bolt in the

post bracket and readjust the pivot

bracket until you can achieve the proper

clearance.

With the post pivot bracket in the optimum position for clearance and freedom of movement, replace the

bolt in a post bracket adjustment hole and secure with washer and lock nut. Return the operator to the

open position and reattach the gate bracket. Recheck the gate operator level and clearance in the open

position. Adjustment of the gate bracket will be necessary if the post bracket was moved. After verifying

clearance, make sure the gate bracket is clamped securely.

Install Gate Bracket

Step 9

Detach the front mount from the gate

bracket. Check that the gate bracket

holes are centered over the scribe

line. Mark the gate in the center of the

gate bracket holes. Remove the gate

bracket and drill the

1

/2” holes through

the gate cross member and attach the

gate bracket using the

1

/2” x 2

3

/4” bolts,

washers and lock nuts.

Attach Operator

Step 10

Make sure the gate is in the open

position and the operator arm is fully

retracted. Attach the operator to the

securely bolted post bracket assembly

and gate bracket using clevis pins,

bushings, and hairpin clips, or optional

Pin Lock

[FM345]

. Verify that the

operator is level, bolts are tight, and

adjust the post bracket assembly if

necessary.