Technical Guide

DAN-LIQ-Turbine Meter-TG-0807

August 2007

Page 3

Daniel

®

Valves In Load Rack Duty

TURBINE METER THEORY

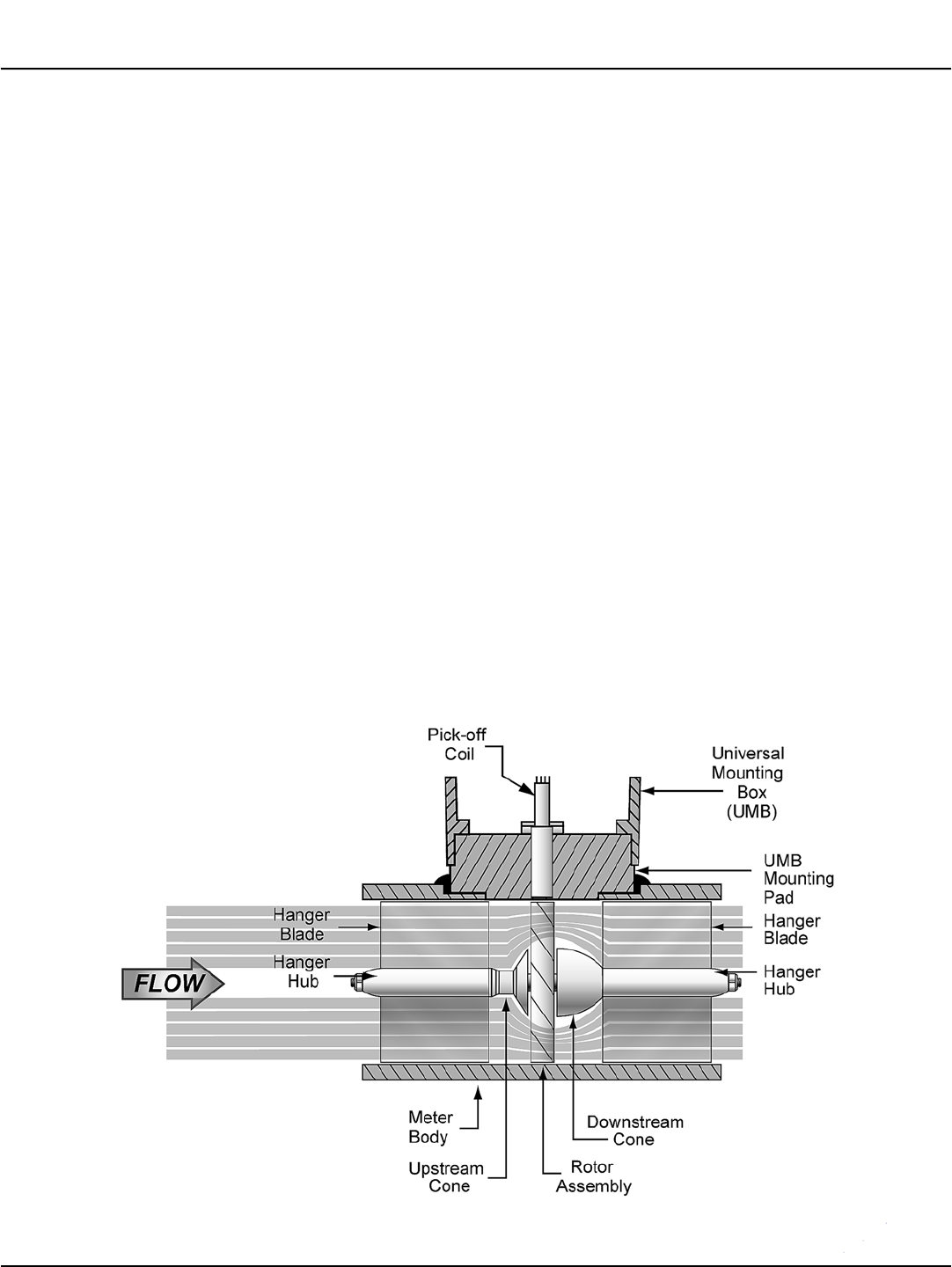

The basic theory behind Daniel’s electronic liquid turbine meters is relatively simple. Fluid ow through the meter

impinges upon the turbine blades which are free to rotate about an axis along the center line of the turbine

housing. The angular (rotational) velocity of the turbine rotor is directly proportional to the uid velocity through

the turbine. These features make the turbine meter an ideal device for measuring ow rate.

The output of the meter is taken by an electrical pickoff(s) mounted on the meter body. The output frequency of

this electrical pickoff is proportional to the ow rate. In addition to its excellent rangeability, a major advantage

of the turbine meter is that each electrical pulse is also proportional to a small incremental volume of ow. This

incremental output is digital in form, and as such, can be totalized with a maximum error of one pulse regardless

of the volume measured.

The turbine meter and associated digital electronics form the basis of any liquid metering system. An expanding

blade hanger assembly holds the turbine rotor in alignment with the uid ow. The angle of the turbine blades to

the stream governs the angular velocity and the output frequency of the meter. A sharper blade angle provides a

higher frequency output. In general, the blade angle is held between 20º and 40º to the ow. Lower angles cause

too low of an angular velocity and loss of repeatability, while larger angles cause excessive end thrust.

FLOW RATE IS PROPORTIONAL TO ANGULAR VELOCITY

Figure 3 below is a cross section of the internals of a Daniel turbine meter. Flow through the turbine meter is from

left to right. The forward and rear suspension act as ow guides so that uid motion through the meter is parallel

to the meter centerline. Flow impinging upon the angular blade causes the rotor to spin at an angular velocity

proportional to ow rate.

Figure 3 - Liquid Turbine Flow Meter Cross Section