78-0013-4441-1-D 11

3M

™

One Pass Mini Fiber Pathway

15.0 Fiber Repair

15.1 Ensure that the root cause for service interruption is

damaged 900 µm.

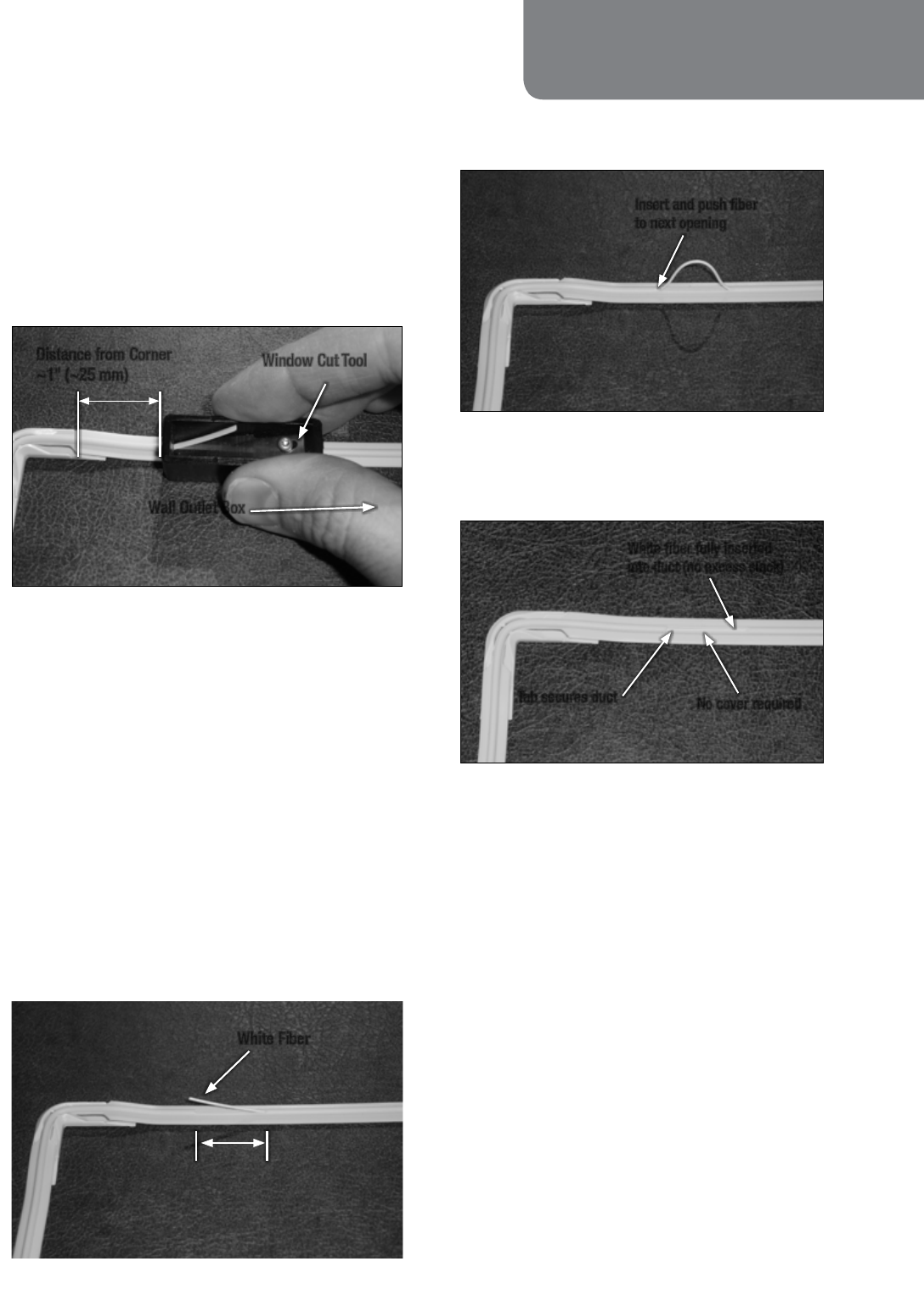

15.2 Working away from the Wall Outlet, make small

window cuts using the Window Cut Tool at every

other corner or turn.

Note: Additional window cuts at other corners may be

made if needed.

Window Cut Tool

Wall Outlet Box

Distance from Corner

~1" (~25 mm)

15.3 Cut connectors/fusion splice sleeves from the ends

of the fiber stored inside the Wall Outlet and Point-

of-Entry (POE) Cover of the damaged 900 µm fiber.

Pull existing (gray) 900 µm fiber from installed duct

and discard per company practice.

Note: If pulling 900 µm is difficult the window cuts made

in step 2 may be used as intermediate pull back locations.

15.4 Wrap 2'-4' (600-1200 mm) of the new white

900 µm fiber into the Wall Outlet to create enough

slack for connector termination and begin pushing it

into the duct.

Note: Keep new 900 µm off of the floor and clean as it

is pushed into the duct to reduce floor debris from being

carried into the duct.

15.5 When the new white 900 µm fiber comes through

each window cut, pull gently at that point to remove

slack.

White Fiber

Cut Length:

~1" (~25 mm)

15.6 Begin pushing 900 µm out the other end of the

window cut until the next window cut is reached.

Insert and push fiber

to next opening

15.7 Repeat steps 5 and 6 until the new fiber is fully

inserted into the duct, through provided furcation

tubing, and into the Point-of-Entry (POE) Box. The

fiber should be flush with each window cut.

White fiber fully inserted

into duct (no excess slack)

No cover required

Tab secures duct

15.8 Terminate new 900 µm fiber per company practice.