10

V700 Windlass

11

V700 Windlass

GB

4. Maintenance

4.1 General recommendations

• After the fi rst two or three anchor recoveries, check the

mounting nuts to ensure that the windlass is still fastened

tightly to your deck, as it should now be bedded-in.

• Regularly wash down the exterior of your windlass with fresh

water.

• Examine all electrical connections for possible corrosion,

clean and lightly grease as necessary.

• Anchor rode splice should be checked regularly and remade

if there is any evidence of wear.

• The Gypsy should be examined on a regular basis, because it

is a high wear item. The Gypsy is designed for short scopes

of chain and will last longer if properly used.

5. Dismantling procedures

Isolate the windlass electrically, before carrying out any

maintenance work.

Isolate the windlass electrically, before carrying out any

maintenance work.

5.1 Gypsy replacement

Remove the Gypsy Drive Cap (31), anti-clockwise using the clutch

operating lever. Withdraw the Drive washer (21), Remove the

Socket Head Cap Screw (40) that retains the Stripper using a

(5mm) Allen Wrench. Pull the Control Arm (30) back to clear the

Gypsy. Remove the Gypsy Assembly (37). To replace the Gypsy,

reverse the above procedure.

5.2 Control arm replacement

This should be carried out with the Gypsy (37) removed as

detailed above. To remove the Control Arm (30). Unscrew the

Control Arm Shoulder Screw (24) using a (4 mm) Allen Wrench

and remove screw. Remove the Control Arm (30) and Torsion

(12) Spring from the base plate. To replace the Control Arm,

reverse the above procedure.

5.3 Main shaft lubrication

Note The geartrain and its bearings have been lubricated for you

with SFG 100 grease and should require no regular attention.

SFG is a white synthetic grease containing PTFE. Use grease

of a similar specifi cation throughout. It is recommended that

the external Drive Shaft components be stripped, cleaned and

re-greased at least annually. To do this, the Gypsy Assembly (37)

should be removed as detailed above. Inspect the Main Shaft (20)

and Gypsy (37) for damage before reassembly.

5.4 Fall safe pawl replacement

This should be carried out with the Gypsy (37) removed as

detailed above. Turn the fall safe lever (34) so it is horizontal.

Remove fall safe shoulder screw (35) using allen wrench. Lift off

fall safe pawl (32). Remove fall safe spring (36). Replace new part

by reversing the above procedure.

5.5 Fall safe lever replacement

Turn fall safe lever (34) so it is horizontal. Remove socket screw

(6) using allen wrench. Remove fall safe lever (34). To refi t use

thread lock on the socket screw (6). Screw down screw (6) fi nger

tight and leave to cure before operating fall safe lever (34).

6. Troubleshooting

6.1 Anchor rode pays out independently

while windlass is not in use

This problem is a result of not securing the anchor rode combined

with the Gypsy Drive Cap (31) being slack. Tighten the Gypsy

Drive Cap using the tool provided and always secure the anchor

rode independently of the windlass whenever it is not being

deployed or recovered.

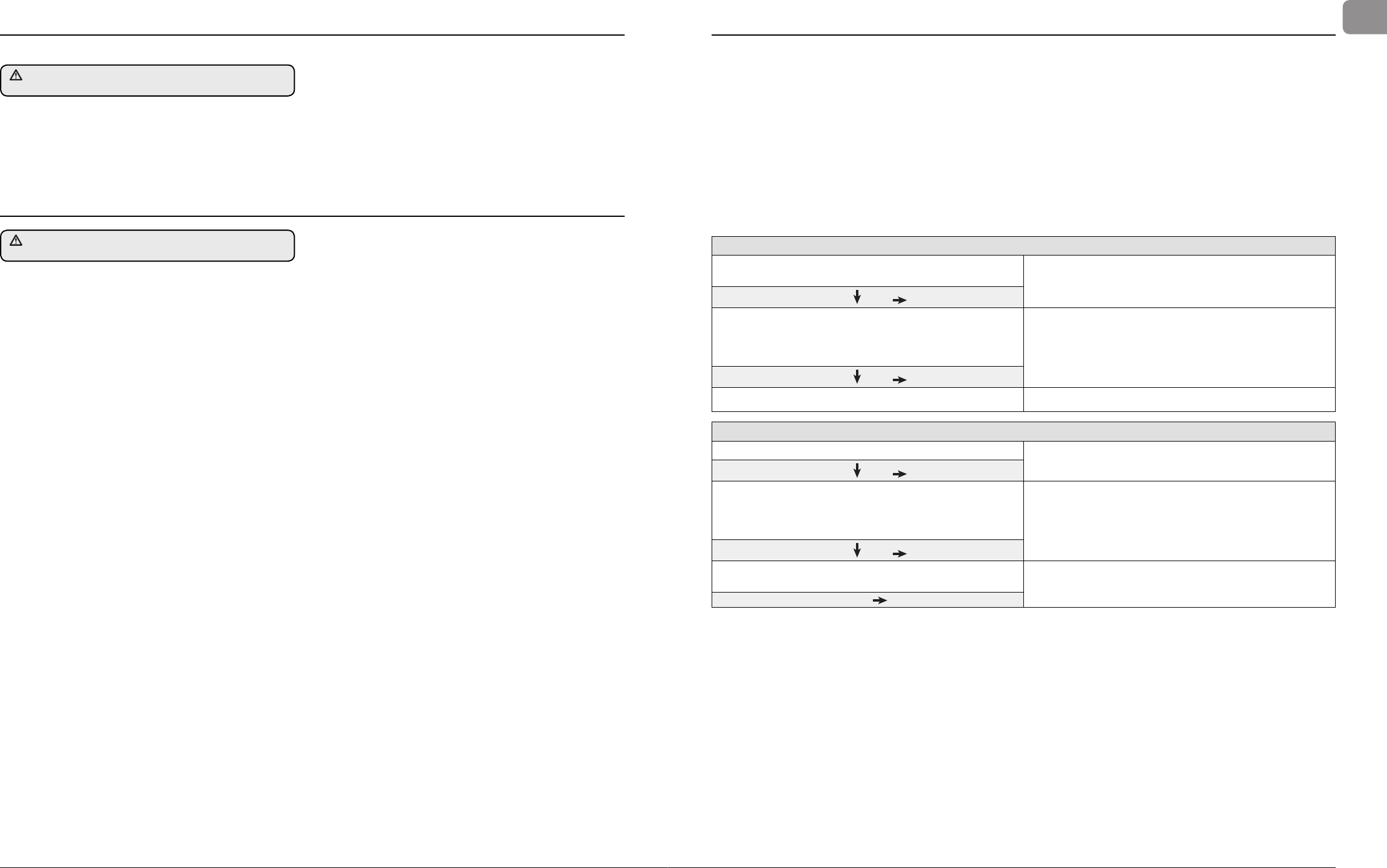

Failure to Operate Troubleshoot Chart: Reversing Toggle Control Switch (Part No. 0052519)

Is there voltage at the input terminal (positive) to the control

switch?

If no voltage is present, the battery isolation switch is OFF, the

breaker is tripped or a fuse has blown. The battery may also

have been dead or disconnected.

YES

NO

Check voltage at the output terminals of the control switch

with the switch on forward then reverse.

Is there voltage at either output terminal for forward then

reverse.?

Control switch is defective.

YES

NO

Replace motor.

Sluggish Operation Troubleshoot Chart

Is windlass overloaded?

Ease the load and ensure the battery is well charged.

YES

NO

Check the voltage across the motor leads with the windlass

on. (Proper voltage is 13.5 V. Constant low voltage will destroy

the motor).

Is the voltage low? (Below 11.0 V on a 12 V system).

There is a severe voltage drop in the circuit.

Check for undersized cables, poor connections or corroded

connections. Also check for resistance across the battery

isolation switch or solenoid. (Feel them to see if they are

heating up).

YES

NO

Is the voltage correct? (Above 11.0 V and anchor is not

fouled).

The motor is defective. Replace the motor.

YES

6.2 Electrical troubleshooting

As with most electrical marine equipment the majority of problems

that arise are electrical in nature. Therefore it is essential that

the proper voltage be maintained. The proper voltage on a 12

Volt system is 13.5 Volts. (Constant low voltage will destroy the

motor). Ensure that electrical cable size is large enough to handle

the current draw imposed upon it and to keep the voltage drop

within acceptable limits. In any circumstance voltage drop due

entirely to cable resistance should not exceed 10%.

Follow the charts to troubleshoot the problem.