6

V700 Windlass

7

V700 Windlass

GB

DO NOT use a permanent adhesive/sealant, e.g., 5200

• Using a 10 mm (

3

/

8

”) diameter drill, make the three holes

for the mounting studs. With a 65 mm (2

1

/

2

”) diameter hole

saw, make the hole for the rode to pass throughwith a 115

mm (4

1

/

2

”) diameter hole saw, make a hole for the motor

gearbox to pass through.

When all the holes have been made, remove the template. To

help avoid water absorption by the deck, apply an appropriate

marine sealant to the freshly cut hole edges.

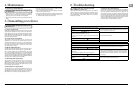

Fig. 1.6-4

• Place the mounting template on the deck or mounting pad

in the desired position for the windlass and hold it in place

using adhesive tape.

• NOTE: Check the scale of the

template matches the winch.

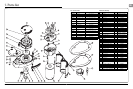

Fig. 1.6-5

• Fully screw the three mounting studs into the base of the

windlass. This can be done, quite simply, using the multi-tool

wrench supplied. Screw the studs into the base fi nger tight,

with the fl ats towards the base as shown (Fig 1.6-5).

• Next, using the wrench on the fl ats, tighten the studs until

they bottom out in their holes. Do this to each of the studs

in turn.

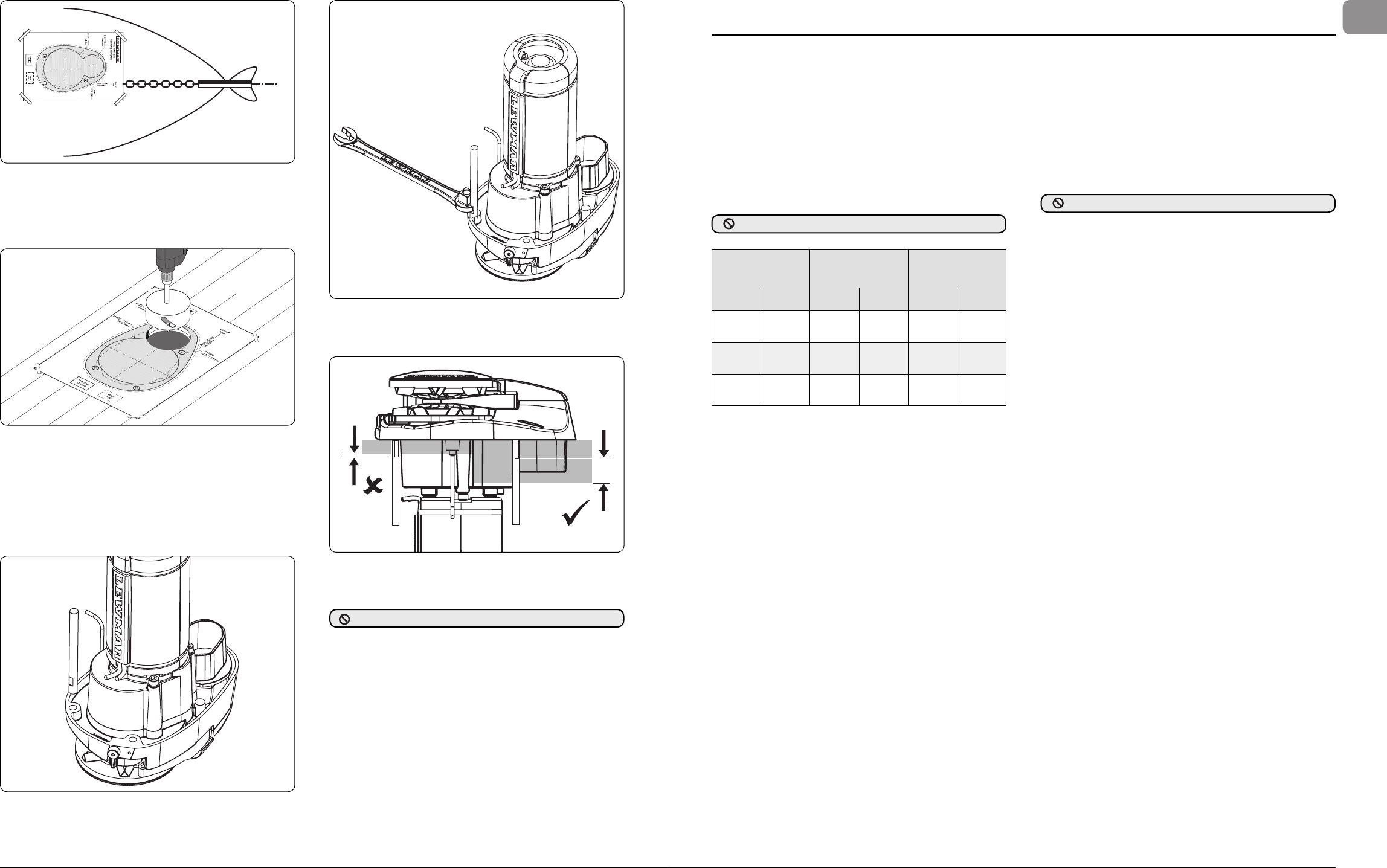

Fig. 1.6-6

As a rule of thumb, if the fl ats on the studs are visible below

deck, the deck and/or any packing is likely to be too thin to

offer adequate support when the windlass is under load.

• NOTE: If using silicone or other rubbery type sealant,

it is advisable to allow curing of the sealant before

fi nal tightening of the mounting nuts. Trim the studs

back to 6 mm (

1

/

4

”) below the fully tightened nuts.

2. Electrical wiring installation

2.1 Electric cable selection

To achieve the best performance and to safeguard your electrical

system it is essential that any electrical windlass be fi tted with

suffi ciently large diameter cable to cope with the current draw

imposed upon it and to keep the voltage drop within acceptable

limits. In any circumstance voltage drop due entirely to cable

resistance should not exceed 10%.

The following table gives recommended cable sizes. The

recommendations are based on total length of cable required,

from the battery, following the route of the cables.

• Total length of cable run is from the battery to the

windlass, and from the windlass back to the battery.

• In Multi Station installations 14 AWG wire (1.5 mm² cross

sectional area, 21/0.30 PVC covered) is used to connect the

switches to the reversing control box.

2.2 Wiring

Plan the installation to suit the controls and give the operator a full

view of the windlass. The wiring system should be of the two cable

fully insulated return type, which avoids possible electrolytic

corrosion problems. We recommend the use of type III stranded,

tinned copper wire with copper crimp terminals. Most modern

installations are negative return (negative ground) but polarity

should be checked. If necessary add a grounding strap between

the mounting studs and an earthing point.

• NOTE: If a Contactor is used in a V700 installation,

the Contactor must be sited in a dry location.

If a contactor is installed in an anchor locker it is exposed to harsh

conditions it is not designed to withstand. Furthermore this type

of installation will void your warranty.

Overload protection, in the form of the circuit breaker/isolator

supplied, must be built into the windlass wiring circuit. This

protects the wiring and prevents undue damage to the windlass

motor, in the event of its being stalled by an excessive load in

service.

It is advisable to site the circuit breaker/isolator in a dry,

readily accessible place. The Breaker/ Isolator supplied must

be manually reset should an overload occur that causes it to trip

to the off position.

• NOTE: Crimp terminals should be used on all wire

ends wherever possible for good electrical contacts.

If you are not sure you understand these guidelines, seek

professional help. Ensure that the installation complies with

USCG, ABYC, NMMA or other local regulations.

2.3 Control switch installation

Follow the mounting instructions supplied with the switch.

Remember, in a Multi Station installation all switches must be

wired in a parallel circuit.

DO NOT confuse cable Length with the length of the vessel!

DO NOT install the contactor in the anchor locker.

Fig. 1.6-3

• Place the base mat in position on the deck, optionally, apply

a suitable sealant to the base of the windlass, any mounting

pad or around the studs.

Fig. 1.6-7

Boat Length

Cable Length

Up To

Cable Size

(m) (ft) (m) (ft) (AWG) (mm

2

)

7.5 25 0 - 10 0 - 33 8 10

9 30 11 - 18 34 - 60 6 16

10.5 35 19 - 24 61 - 80 4 25