LANIER – 1/3

rd

Scale Laser 200 ARF -INSTRU CTIONS

© 2002 Lanier R/CPage-11

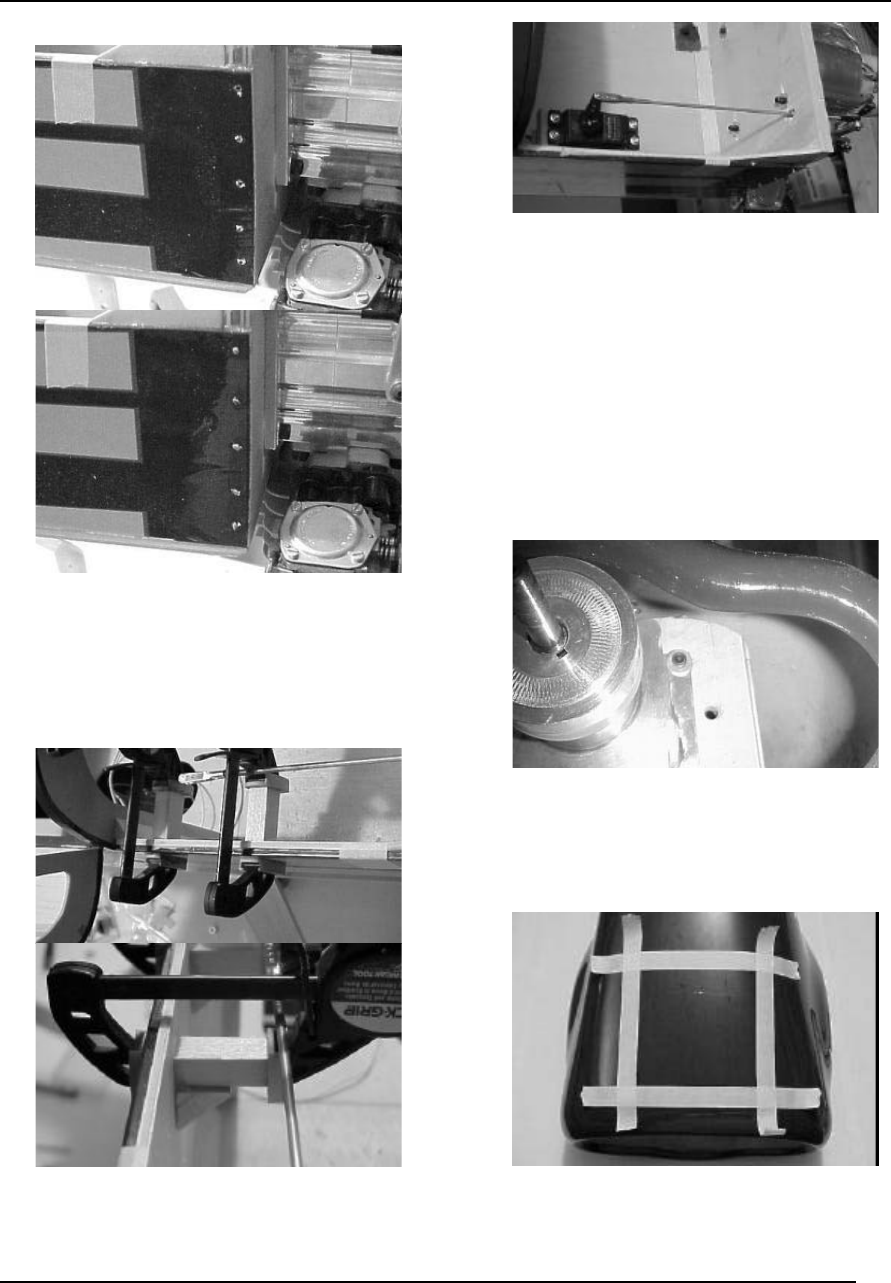

firew all, behind the blind nuts.

69. D rill (5) 3/32” holes on each side of the firew all,

through the fu se sides about 1” deep. Press a

w ood toothpick into the hole, then cut off flush

with som e wire snips. A pply several drops of

thin CA on each toothpick.

70. M ark on the firew all the location where the

throttle contro l rod should pass through. Drill

the marked hole with a 1/8”aircraft drill bit.

71. U sing your servo as a guide, glue the two

hardw ood servo blocks to the fuse side using 30

minute epoxy. Cut a sm all piece of balsa

triangle stock to fillet the servo rails and fasten

with CA.

72. M ake sure your carburetor and throttle servo are

at low position. Reverse your servo if necessary.

Thread the 2-56 clevis on the 12” rod, then snap

the clevis on the servo arm. Install an EZ

connector in the hole on your carburetor

approximately the sam e length of the servo arm.

Trim the throttle control rod to approximate

length, then insert through the hole in the EZ

connector. Tighten the connector enough to test

the throw of the servo and adjust as needed to

allow for maximum throw , but not bind the

servo. When satisfied, trim the control rod to ¼”

past the EZ connector. In stall the servo horn

screw . When everything is fit, th en fuel proof

the firew all with polyurethane or thinned epoxy.

73. Test fit the cow l over the engine to see what

needs to be relieved.

SHAVE TH E

TOP CORNERS OF TH E

FIREW ALL TO ELIM INATE

RUBBING ON COW L.

74. U se masking tape to mark the areas that need to

be rem oved for the head of the engine to clear

the cow l, then test fit.