12

Level

Installation, operation & maintenance instructions

IP152, Rev A

D

April 2012

When fitting a spare or replacement switch mechanism

IMPORTANT NOTE

If a spare switch mechanism is fitted at any time, it is important that the magnet system is left in the correct mode.

After installation of a replacement switch mechanism, always check that the B-B contacts are made, assuming the chamber is

empty of liquid. If the chamber is full of liquid, then A-A contacts should be checked to ensure they are made.

If it is found that a switch mechanism is not in the correct mode, then the liquid level in the chamber should be raised such that

the primary float magnet passes through the switching point. Lowering the liquid level will then cause the float magnet to fall

back through the switching point, thus leaving the switch mechanism in the correct operating mode (For a control operating as

low level alarm, the liquid level should be first lowered then raised back to ensure the switch mechanism is in the correct

operating mode).

Full fitting instructions are supplied with each spare or replacement switch mechanism.

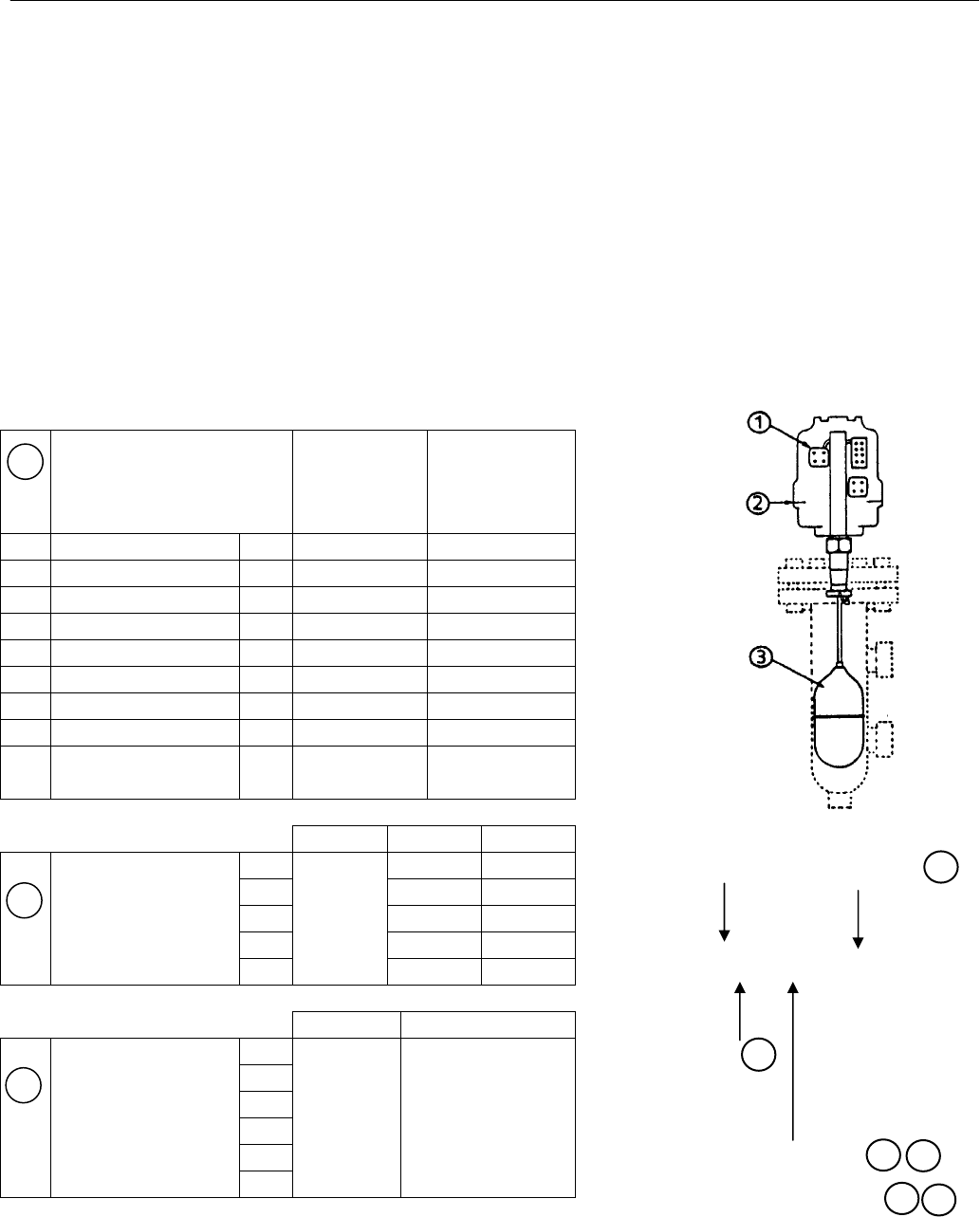

Se

ries B Series X Series D

Complete float

assembly, comprising

float unit and

rod and magnet

assembly

11F

N/A

Sealed

Chamber

Contact factory with

full model number and

complete assembly

can be supplied

12F

13F

14F

17D

Switch mechanism kit

comprising

Switch mechanism and fittings

Series B,X,D

Weatherproof

Series B,X,D

Weatherproof

4 Contact 5 Amp D4 SK178 SK178

4 Contact plated P4 SK179 SK179

4 Contact 10 Amp X4 SK180 SK180

4 Contact sealed H4 SK181 SK181

8 Contact 5 Amp D8 SK182 SK182

8 Contact plated P8 SK183 SK183

8 Contact 10 Amp X8 SK184 SK184

8 Contact sealed H8 SK185 SK185

Sales Kit SK190 SK191

Series B Series X Series D

Float unit only 11F

N/A

Sealed

Chamber

SK192 SK192

12F SK193 SK193

13F SK194 SK194

14F SK195 SK195

17D SK196 SK196

1

1

XC13F S7A 1 D8/112

Series

Mechanism

7 = Flameproof

4 = Weatherproof

Float

3

1

1

2

2

1

2