INSTALLATION PROCEDURES Eskimo Ice Installation Manual - Remote System

8 L-2448B ENGLISH

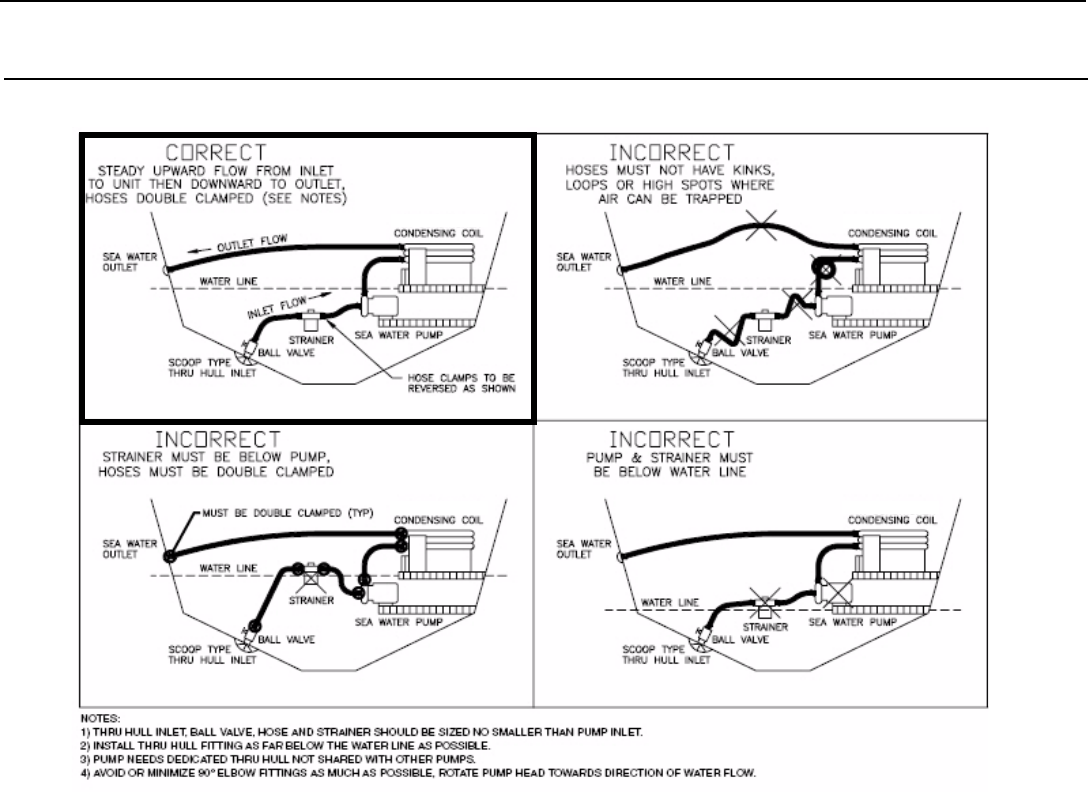

Figure 3: Seawater Piping Recommendations

Thru-Hull Inlet Fitting

A separate thru-hull fitting must be installed for each seawater pump. Do not attempt to draw water from the thru-hull fitting of an

engine, generator, or other device.

Install a scoop-type thru-hull fitting:

1. Drill a properly sized hole for the thru-hull fitting as far below the water line and as close to the keel as possible.

2. Make sure the scoop of the thru-hull fitting faces the bow.

3. Bed the scoop with marine sealant designed for underwater use, and tighten the nut onto the thru-hull to secure it.

Seacock

The seacock must be accessible and easy to close in case of emergency or to clean the strainer.

1. Install a full-flow seacock directly onto the thru-hull fitting.

2.

Us

e threaded-seal tape to seal the threads.

Seawater Piping

• Only use reinforced marine-grade hose or other suitable piping (PVC, CPVC, cupronickel, or stainless steel).

• Double clamp all hose connections.

• Use only plastic, bronze, or stainless steel fittings (do not use brass).

• Avoid loops or dips in all hose runs.

• Make sure enough hose is used to allow for future removal of components.

• Use the correct size hose, fittings, and components: 5/8” seawater hose, 3/4” inlet. Note that the pump inlet piping

(including thru-hull and strainer) may need to be larger than the outlet pipe size. Do not use pump connections to

determine hose size.

• The "pump inlet" recommended pipe size includes all fittings and hose up to the pump connection (thru-hull, seacock,

strainer, hose, manifold). The "pump discharge" recommended pipe size includes all fittings and hose from the pump

discharge up to the overboard discharge, and should be a minimum of 5/8”.