SWR • SWC • SWD Swing Gate Operator Installation Guide - 5 - 227965 Revision X13 3-28-2008

Gate Arm Installation (Cont.)

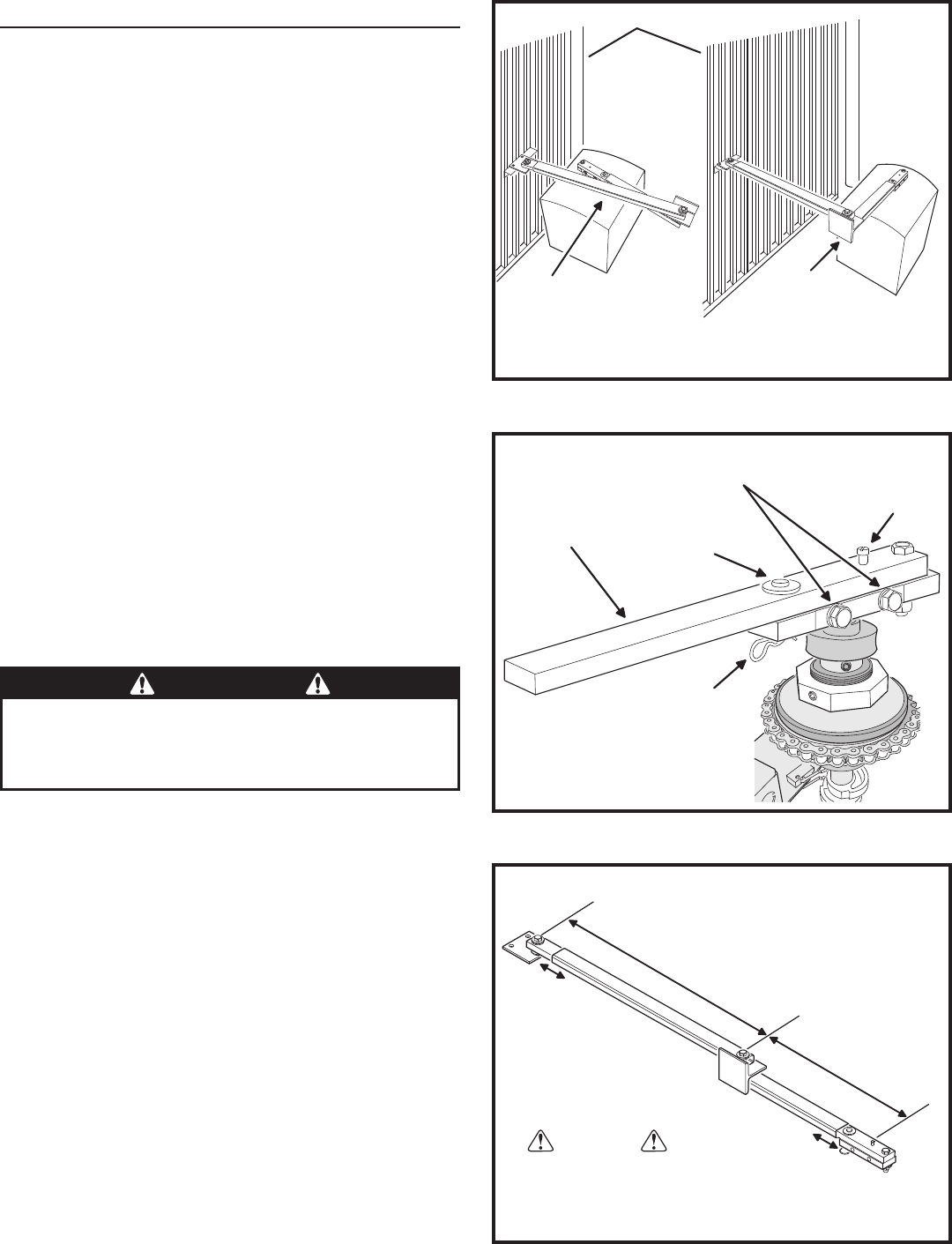

Choosing Good Harmonics

Good harmonics are necessary to minimize wear and tear

on the operator. The gate will have smoother starts and stops

when the arm is installed with good harmonics. Figure 5

shows an example of good and bad arm harmonics.

Installing the Gate Arm on the Operator

The hex cap screws (see Figure 6) in the side of the crank

assembly are shipped loose for placement on the operator

drive shaft. Once in place, tighten these cap screws in place

by applying 75 ft-lbs of torque. If it becomes necessary to

remove the crank, you can do so by loosening these bolts.

The arm can also be disconnected for manual operation of

the gate by removing the disconnect pin.

Setting the Arm Lengths

Most installations will use the standard dimensions specifi ed.

The dimensions shown in Figure 7 can be used to adjust and

set the arm. If non-standard mounting is required, contact

the factory for information.

Once the arm lengths have been determined, use clamps

to temporarily attach the solid bars to their sections of

rectangular tubing. If clamps are unavailable, you may also

tack weld the parts in place. It is recommended that you

check the arm for proper action and full gate travel

before fully welding the parts together. REMOVE THE

GATE ARM BEFORE WELDING! Apply Krylon

®

metallic

gold spray paint or equivalent to touch up welds when

fi nished.

Figure 7. Setting Gate Arm Lengths

A

B

C

SET LENGTH

AND WELD

SET LENGTH

AND WELD

CLAMP OR TACK WELD,

THEN TEST ARM ACTION

BEFORE FULLY WELDING

CAUTION!

36-1/2"

TYPICAL

22"

TYPICAL

LINK

ARM

CRANK

ARM

Figure 5. Gate Arm Harmonics

GOOD

HARMONICS

BAD

HARMONICS!

GATES SHOWN OPEN

GATE ARM FOLDS

OVER ITSELF

GATE WILL HAVE SOFT

STARTS AND STOPS

CRANK END OF

GATE ARM PARALLEL

TO OPEN GATE

GATE ARM JERKS AT START

AND WILL TRANSMIT FORCE

INTO GATE AND HARDWARE

Figure 6. Installing Gate Arm on Operator

CRANK END OF

GATE ARM

DISCONNECT

PIN

PULL

PIN

RAIN CAP

SHOLDER BOLT

ALIGN CRANK ARM ON OPERATOR

THEN TIGHTEN THESE TWO BOLTS

CAUTION

DO NOT WELD THE GATE ARM WHILE IT IS ATTACHED TO THE

OPERATOR! Connecting the welder’s ground to the operator’s

frame will cause the arc welding current to pass through the

operator parts, severely damaging or destroying the operator.