Operation

6 3A0101C

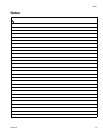

Drum Installation/Replacement

Installation

NOTE: Carbide Flail Cutter drums do not require

specific orientation or direction. Carbide Millers and

Diamond Blades are directional. They should be

stacked so that the arrows on the Millers and Blades

face the same direction as the rotation of the drum.

270 and 390 models are designed for “forward cut”

grinding (the drum rotates in the same direction that it

travels). 480 and 630 models are design for “reverse (up

cut)” grinding (the drum rotates in the opposite direction

that it travels).

1. Slide replacement Drum onto hex shaft.

2. Replace Drum Access Panel (H).

3. Lower Drum Adjustment Dial (D) and pull Drum

Engage Lever (E) so drum rests on ground.

Door pin and hole should line up.

4. Tighten four bolts on Drum Access Panel (H).

5. Turn Drum Adjustment Dial (D) to maximum height.

Removal

1. Remove four bolts and Drum Access Panel (H).

2. Slide drum off of hex shaft.

Carbide Miller

Diamond Blade

ti15142a

ti15141a

Forward Cut (270/390 Models)

Reverse (up cut) 480/630

ti15138a

ti15137a

ti14766a

ti14764a

ti14756a

ti14755a

ti15256a

ti15257a

ti14767a

ti14765a