Maintenance

12 3A0101C

Maintenance

The following steps should be performed to maintain

proper operation and sustain the life of the GrindLazer.

BEFORE OPERATION:

• Visually inspect the entire unit for damage or loose

connections

• Check engine oil (see engine manual)

• Check drum bushings and cutters

• Check drum for uneven wear

• Check for proper tire pressure

DAILY:

• Insert and clean air filter element

• Clean dust and debris from exterior of unit (do NOT

use pressure washer or other high pressure clean-

ing equipment)

• Check engine oil level and fill as necessary

• Check and fill gas tank

• Remove air filter cover and clean element. Replace

element if necessary. Replacement elements can

be purchased from your local engine dealer.

AFTER THE FIRST 20 HOURS OF OPERATION:

• Drain engine oil and refill with clean oil. See engine

manual for correct viscosity.

EVERY 40-50 HOURS OF OPERATION:

• Change engine oil (see engine manual)

• Grease wheel bearings

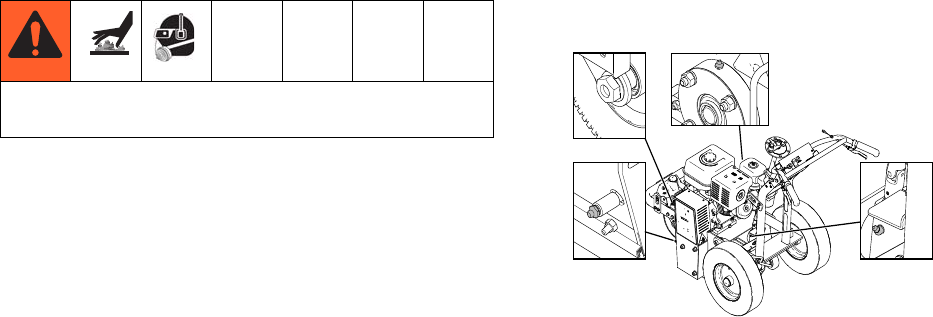

• Insert grease into the grease fittings on the drum

mount and center hinge

AS REQUIRED:

• Check drive belt and tension and tighten or replace

as needed

For additional information about engine mainte-

nance, see Honda (270 and 390 models) or Briggs

and Stratton (480 models) engine manual.

Caster Wheel Maintenance

EVERY MONTH:

• Grease wheel bearing

• Check pin for wear. If pin is worn out there will be

play in caster wheel. Reverse or replace pin as

needed.

• Check caster wheel alignment as necessary. To

align: loosen set screw, align wheel, and tighten

screw.

Front Swivel Tire Alignment

1. Loosen cap screw.

2. Rotate front wheel fork left or right, as necessary, to

straighten alignment.

3. Tighten cap screw. Push GrindLazer and let it roll

with hands off of GrindLazer.

NOTE: If GrindLazer rolls right or left, repeat steps 1

and 3 until GrindLazer rolls straight.

Avoid touching engine and drum after use until they

have completely cooled.

ti14760a