Cutting Drum Assemblies

3A0101C 11

Cutting Drum Assemblies

Different drum configurations can be used for different

applications. There are three different types of drum

assemblies compatible with the GrindLazer: carbide

flails, carbide millers, and diamond blades.

Carbide Flail Cutter/Assembly

Gradually adjust depth down to remove marking line

(minimal amount of paved surface should be removed).

Carbide Miller Cutter/Assembly

Best results for deep cuts are achieved by making sev-

eral thin passes. A single pass should be no deeper

than 1/32 in. or damage to rods and cutters could occur.

Diamond Blade Assembly

(480/630 Models Only)

Watch Depth Control Wheels (K) during operation; if

wheels are spinning, proper depth is being achieved.

Cutter and Drum Assemblies

• The engine should not labor. Run engine at full

speed and adjust forward speed to fit the work being

performed. Harder concrete surfaces will have to be

cut at a slower pace than asphalt or other softer sur-

faces.

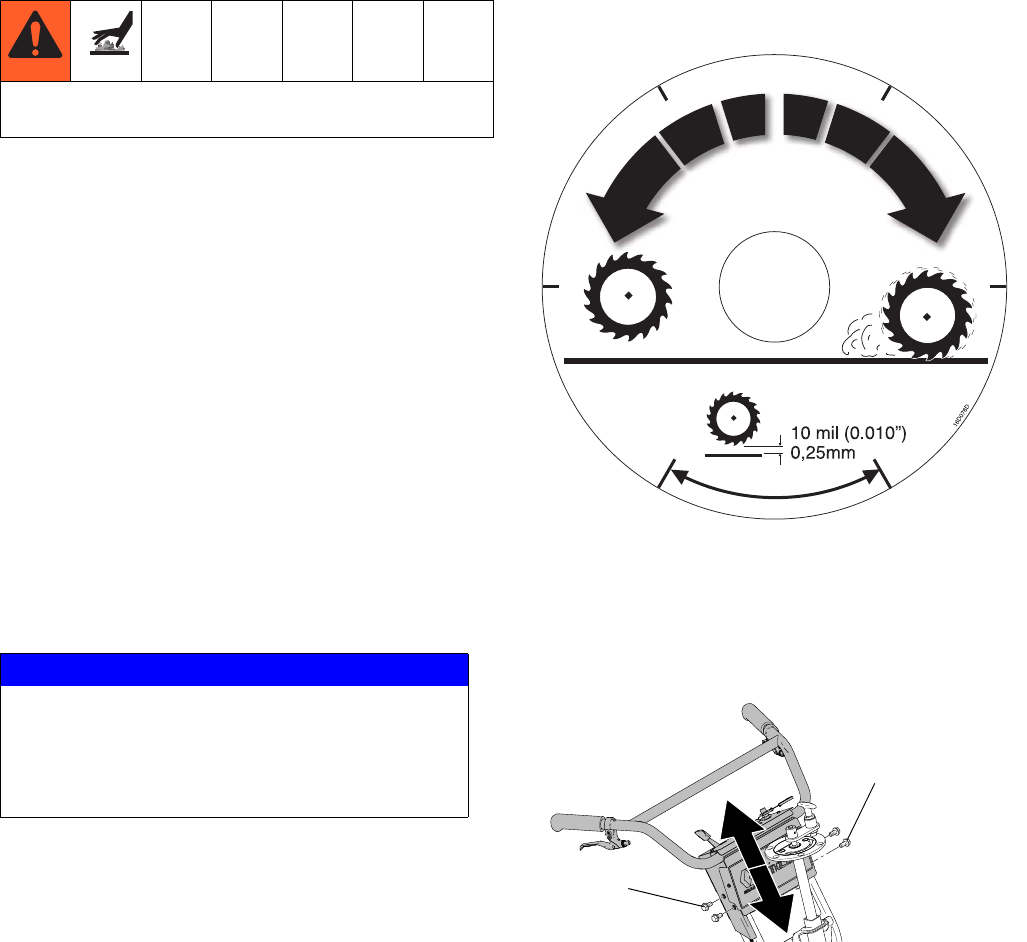

NOTE: Each increment on Drum Adjustment Dial (D) is

0.010 in. (0.25 mm) depth change of cutting drum.

Handle Bar Adjustment

To adjust handle bar: remove four screws (S), slide

handle bar to desired height, and replace screws and

tighten.

Avoid touching or handling drum after use until it has

completely cooled.

NOTICE

Diamond Blades are designed to be cooled by air-

flow around the blades. Lift blade out of cut every

10 to 15 seconds, then run at full speed for several

seconds to prevent excessive heat build-up which

could damage the blades.

S

S