Troubleshooting

313879B 21

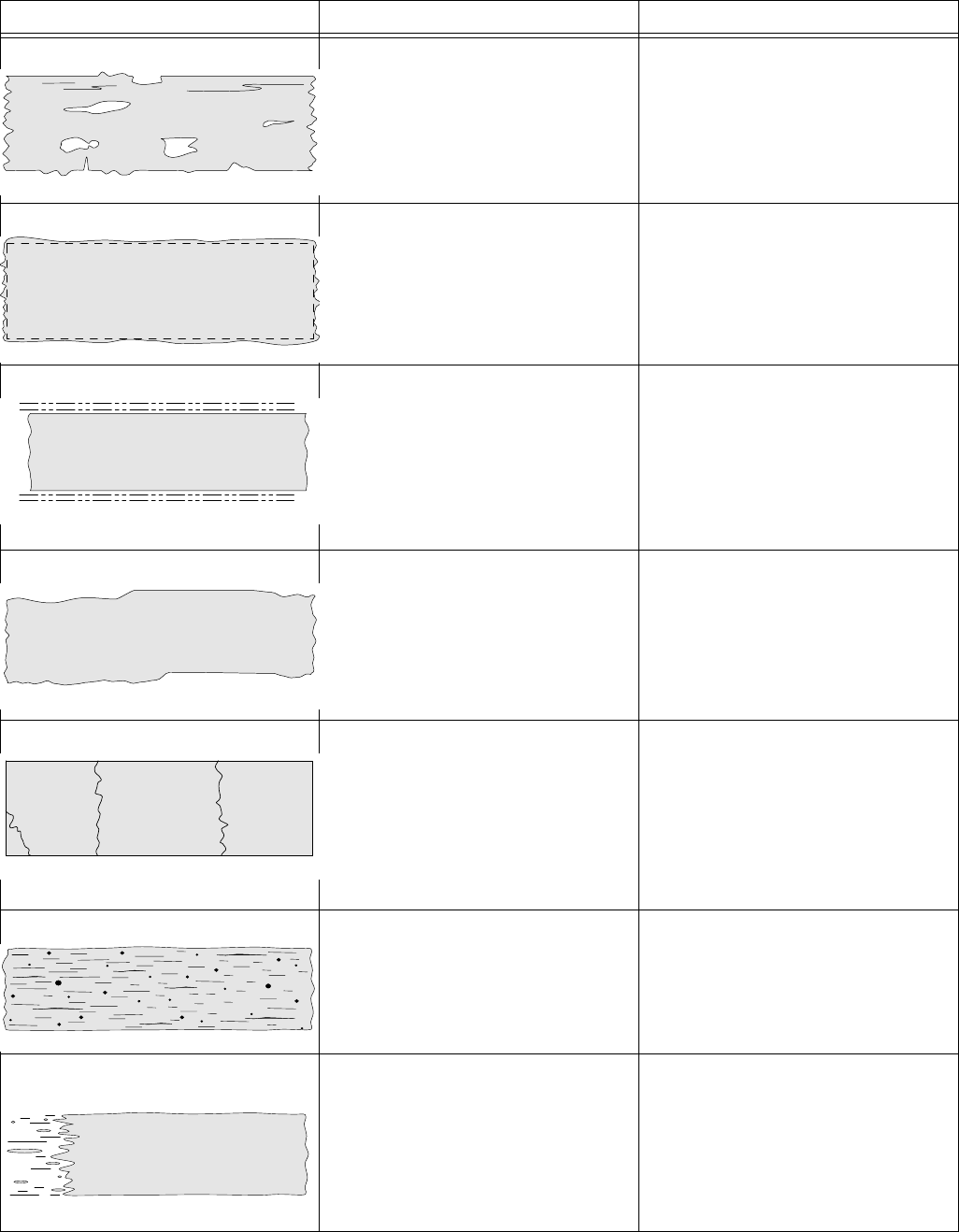

Ragged edges and gaps in line • Material temperature is too low

• Thermolazer

™

speed is too fast

• Raise material temperature

• Wait for change in ambient condi-

tions to remove moisture

• Reduce Thermolazer

™

speed

Swollen rounded line • Material temperature is too high • Lower material temperature

Material shadows on sides • Uneven road surface

• Die is not evenly riding on sub-

strate

• Apply to even road surfaces

• Remove debris from screed box

lever rod

• Inspect/replace damaged screed

box lever rod/lever arm

Line is wavy • Strong road surface camber

• Incorrect Thermolazer

™

operation

• Apply so camber does not influ-

ence application

• Use correct application methods

(for example, try locking swivel

wheel)

Cracks in line • Cracks in road surface

• Temperature stress from

overheating

• Material applied too cold

• Material applied too thin

• Repair cracks

• Lower temperature in material

• Increase material temperature

• Slow Thermolazer

™

speed to

apply thicker material

Rough edges and lines in surface • Material temperature is too low

• Material is overheated or scorched

• Moisture in road surface

• Raise material temperature

• Lower material temperature

• Wait until road surface is dry

Jagged line ends; material drips

between lines

• Die does not fully close

• Debris caught in die

• Worn die gate

• Worn die trough

•Broken spring

• Clean die

• Clear debris from die

• Replace die gate

• Replace die trough

• Replace spring

Problem Cause Solution

ti14511a

ti14512a

ti14513a

ti14514a

ti14515a

ti14516a

ti14517a