Securing Bead Dispenser Wheel

14 313879B

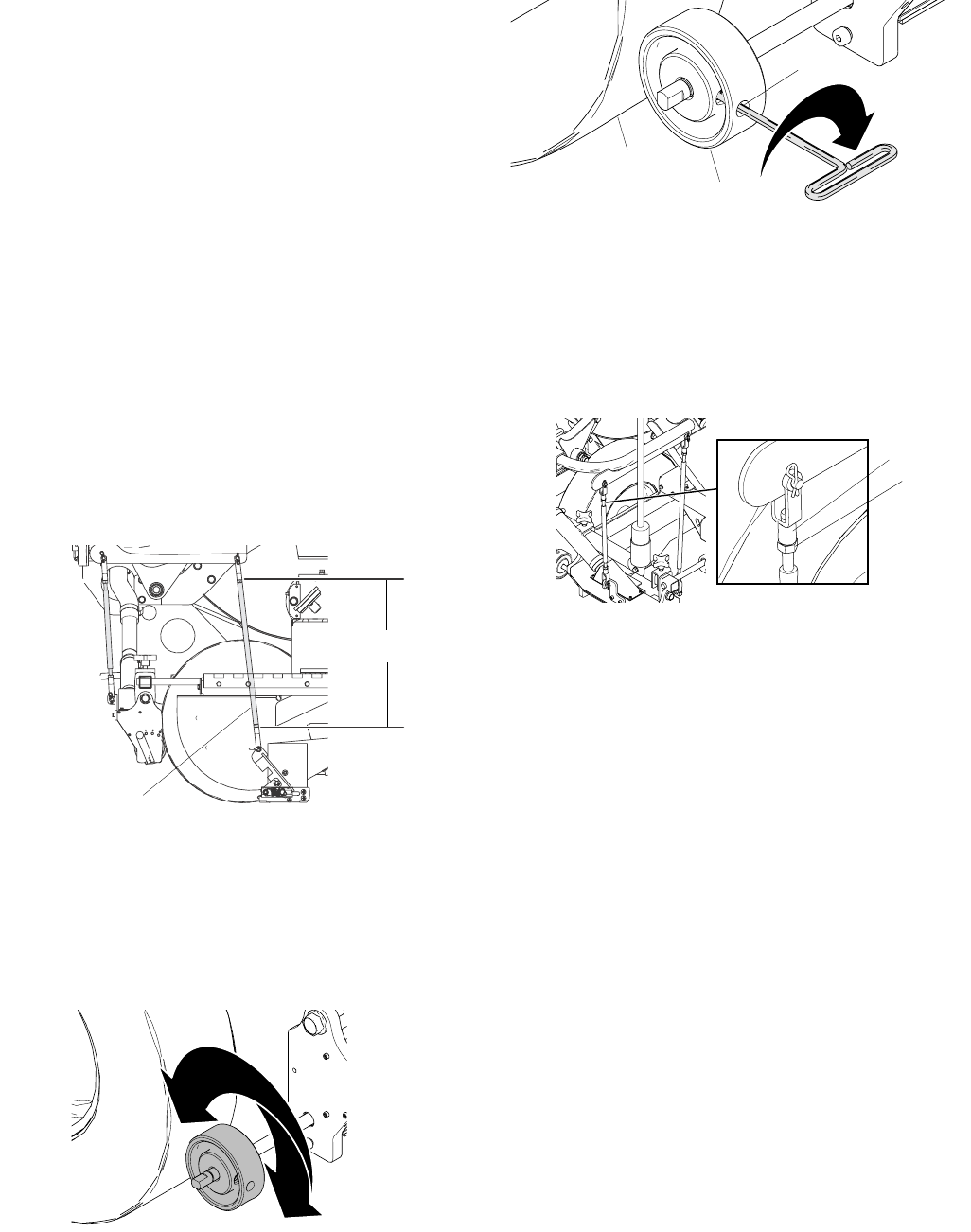

Securing Bead Dispenser Wheel

To properly dispense beads, drive wheel (27) must be in

direct contact with tire (89). If drive wheel (27) becomes

loose and/or starts to slip, use allen wrench to tighten

set screw (211).

NOTE: To ensure proper contact between drive wheel

(27) and tire (89), make sure air pressure is always at 60

psi (4.14 bar).

Linkage Rod Adjustment

Adjustments can be made to linkage rods by removing

clevis cotter hairpin (268), clevis (179) pin, loosening

nuts (128), and then turning clevis as required to

lengthen or shorten rod connectors.

To ensure proper application of beads and thermoplas-

tic, make sure screed box linkage rod (182) measures

16.875 in. (42.8 cm). Be sure to measure where nut

(128) meets clevis (179) when checking for proper link-

age rod length.

Adjust the bead box linkage rod (181) so bead box drive

is touching ThermoLazer tire when screed box is in

down (but not open) position. A slight downward force

on the bead box linkage should be required when insert-

ing the clevis pin through the clevis deployment bar.

1. With screed box in down (but not open) position,

rotate the bead box wheel by hand.

2. If the wheel does not cause the ThermoLazer tire to

rotate both forward and backwards, loosen nuts

(128), clevis cotter hair pin, clevis pin, and rotate the

clevis (179) one turn counterclockwise.

3. Reconnect clevis to deployment bar and again

rotate bead box wheel to see if adjustments cause

ThermoLazer to move forward and backwards.

4. Continue to rotate clevis 1/2 turn counterclockwise

until rotating bead box wheel causes ThermoLazer

to move forward and backwards.

89

27

211

ti14564a

16.875 in.

ti14565a

182

128

179