Page 18

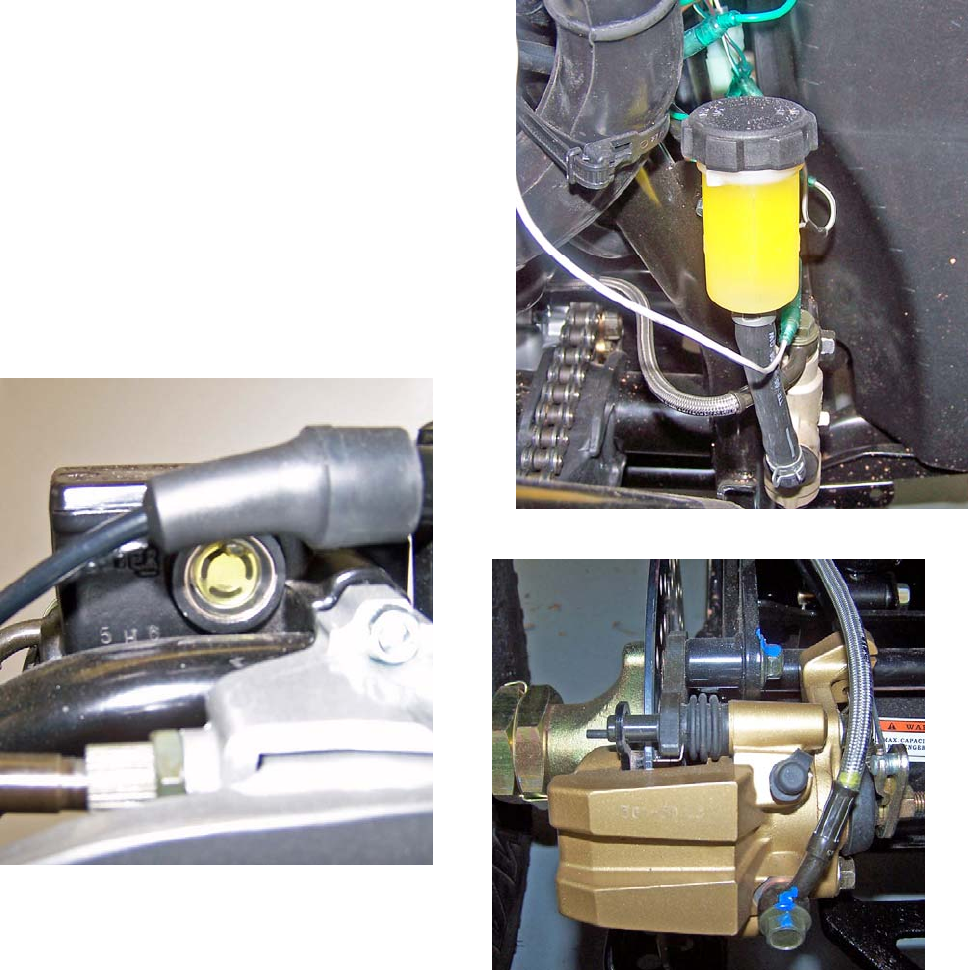

Brake fluid Dot-3 SAE-J1703 grade.

Inspect brake line joints and wheel cylinders for

leaks and repair as needed.

Apply the brakes by squeezing the brake lever.

The level should stop with the brakes fully apply

and at least ½” / 13mm of clearance between the

brake lever and the handle bar grip. It there is

less than ½” / 13mm clearance or the lever is not

firm the brake pads may require changing. Or the

line may need bleeding.

Insect the brake pads for wear and be sure they

are clean and free of dirt and mud. Brake pad

service limit is 0.06” / 1.5mm thick. Replace pads

that are at or below the service limit.

Inspect the brake rotor for cracks and warp.

Replace defective rotor as required.

The brakes are equipped with a wear indicator to

alert you when your brake shoes need replacing.

Apply light pressure to the brake lever and slowly

push the unit forward. If you hear a high pitched

metallic scraping sound, you need to replace your

brake shoes. The minimum shoe lining thickness

is 1.5mm.

DO NOT RIDE A UNIT WITH WORN

BRAKE PADS or DAMAGED ROTOR.

Rear Brake System Inspection

Visually inspect the brake hose for any signs of wear

or leaks.

Check the fluid level in the fluid reservoir by

checking the site glass for the level.

The fluid Reservoir should be at least ¾ full when

the unit is setting on a level surface.

Test the brakes by applying pressure to the brake

pedal and trying to push the unit forward. If the

wheel rotates while the brakes are applied, check

your fluid level and brake pads. If the brake pedal

feels spongy or does not stop when squeezed, you

may have air in the lines. All air must be purged from

the brake lines for the disc brake to operate properly.