9

Level

Installation, operation & maintenance instructions

IP152, Rev AD

April

2012

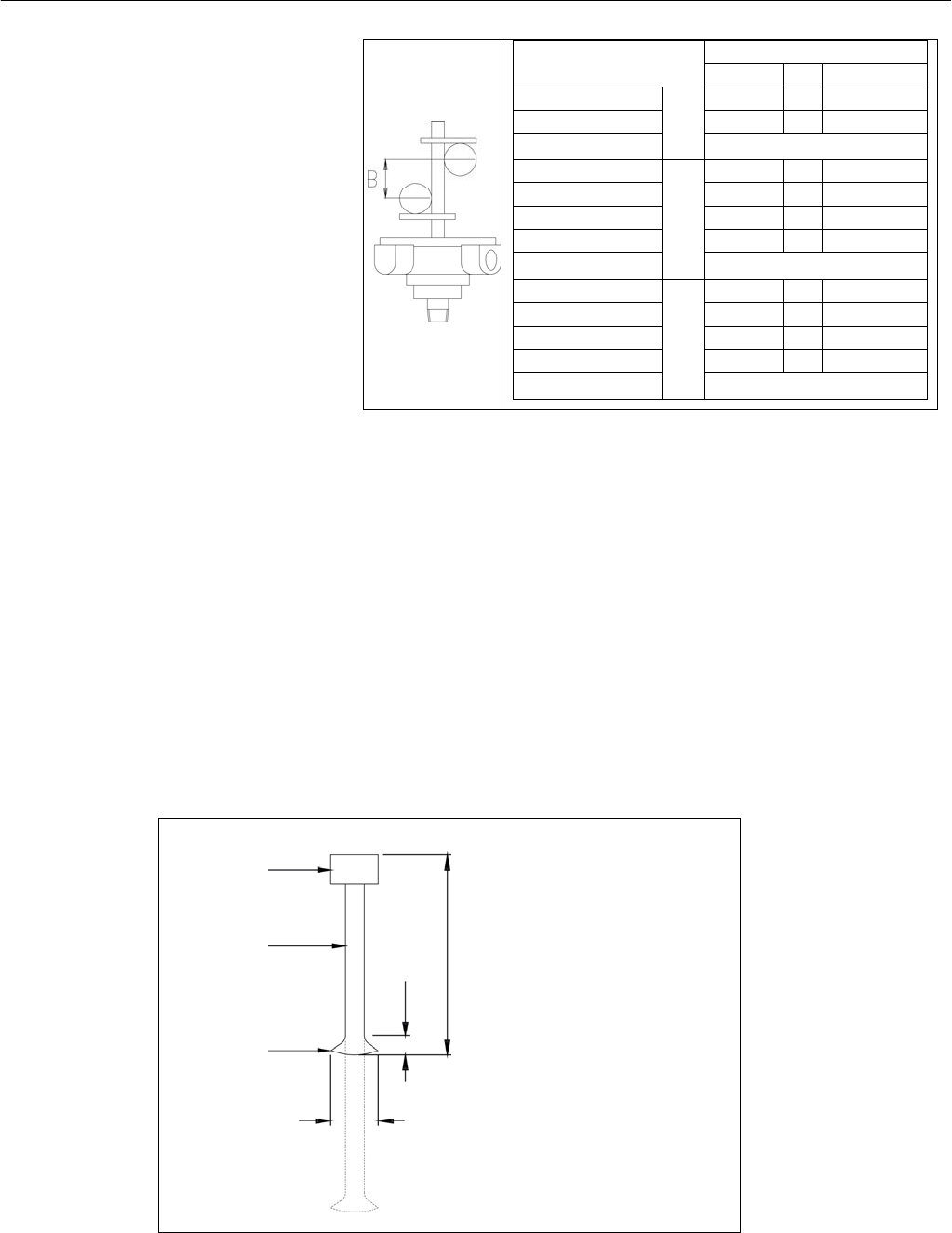

Switching Point Adjustment

Each switch mechanism is mounted on a

bracket, which is secured on the pressure

tube by a locking screw and lock nut.

These can be loosened, allowing the bracket

to be adjusted up or down as required. Always

ensure that the small pressure plate between

the locking screw and pressure tube is in

place before re-tightening the locking screw

nut.

Important note: Switches can not be

adjusted outside of the range set by the stops

on the pressure tube. Displacer operation

controls are covered in Installation Instruction

booklet IP153

Float Rod Length Adjustment

The highest operating level given by the float rod as supplied can be made higher (i.e. nearer the mounting point) by shortening

the float rod on site, as follows:

Remove float unit from control by locating the Stop Assembly in the base of the 1”NPT threaded boss and easing the spring clip

out of the two locating holes in the pressure tube. The rod and the magnet assembly can now be withdrawn from the pressure

tube. Undo the hexagonal float adaptor to remove the float from the rod, and slide the adaptor up the rod. Hacksaw the stainless

steel rod to the required length according to the diagram below, and then re-clench the rod end in a vice as shown. Re-fit the

float, ensuring the spring washer is used between float and adaptor.

Re-fit the float unit to the switch head, ensuring that the magnet is free from swarf and debris. Locate the two ends of the spring

clip in the two cross holes in the pressure tube; ensuring that the rod and magnet assembly are free to move vertically in the

pressure tube and that it is securely retained by the Stop Assembly.

Enclosure type

R7A

R7I

R4N

Switch Mechanism Type

D4, P4, X4 H4 D8, P8, X8, H8

Max. No. Switches 1 1 7

Sw. Adjustment ‘B’ 7 7 7

Max. Wet switching

differential

Type 11F, 12F, 13F, 14F : 20mm

Max. No. Switches

S7A

S7I

S4N

4 4 2

Sw. Adjustment ‘B’ 94 94 94

Max. Sw Crs ‘B’ 94 94 94

Min. Sw Crs ‘B’ 7 0 56

Max. Wet switching

differential

Type 11F, 12F, 13F, 14F : 114mm

Max. No. Switches

L4N

6 6 3

Sw. Adjustment ‘B’ 194 194 194

Max. Sw Crs ‘B’ 194 194 194

Min. Sw Crs ‘B’ 7 0 56

Max. Wet Switching

differential

Type 11F, 12F, 13F, 14F : 214mm

Minimum lengths with switch heads to

give highest operating level of 190mm

R7A R71 R4N : 316

S7A S71 S4N : 421

L4N : 521

Magnet

Rod

Cut &

re

-

clench

3.5 min

3.0 min