4

Level

Installation, operation & maintenance instructions

IP152, Rev A

D

April 2012

Electrical characteristics

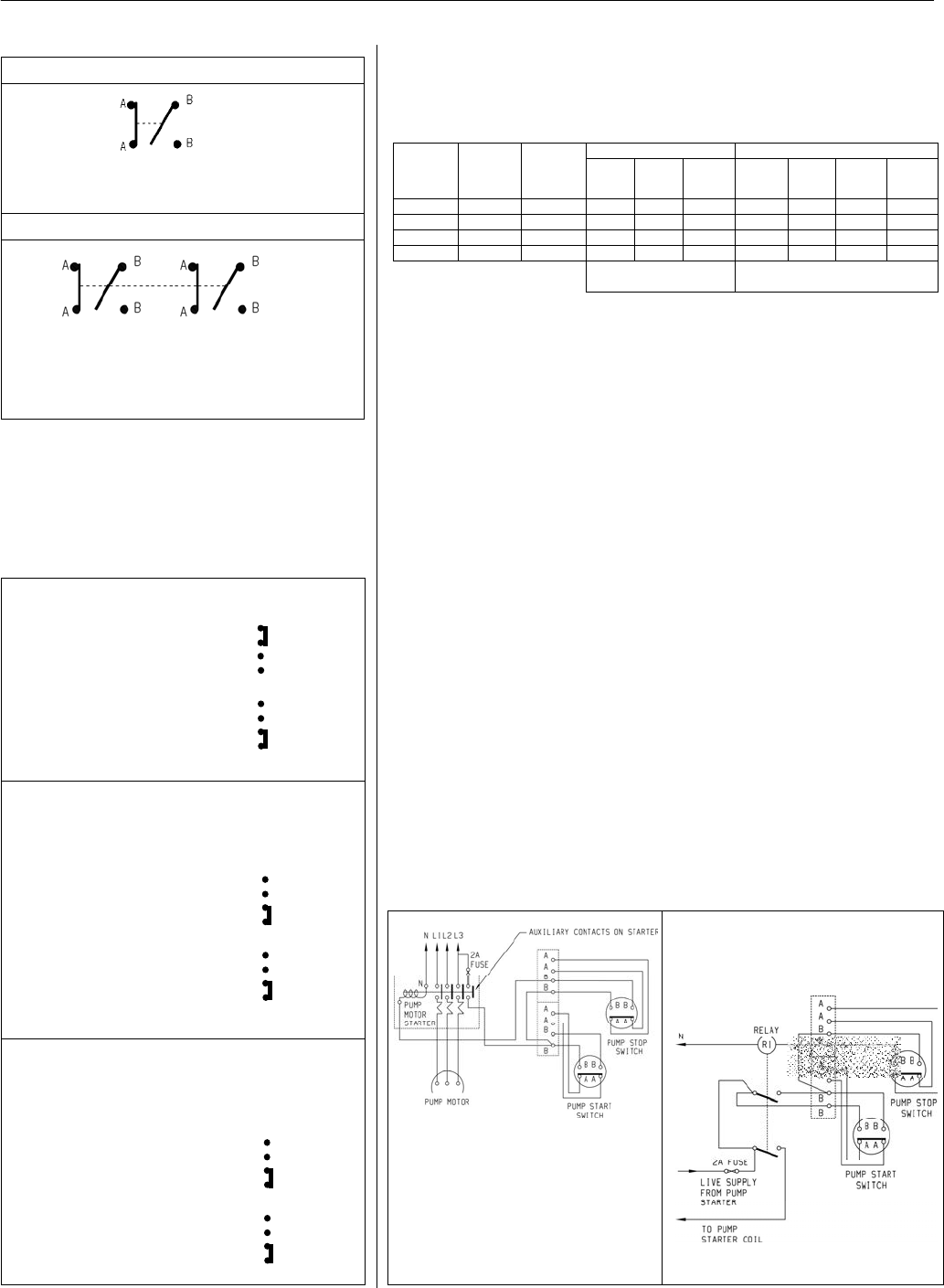

4 Contact Type : D4, X4, P4, H4

2x independent SPST

AA make on rise : BB make on fall

8 Contact Type : D8, X8, P8, H8

Double pole double throw

(4x independent SPST)

AA make on rise : BB make on fall

Note: For DPDT operation, installer must

common any one pair of A and B wires in the

terminal block for each of the two ends of the

switch mechanism.

Wiring Examples

Each switch mechanism has flying leads which are factory wired to ceramic

terminal blocks fixed in the switch enclosure.

Electrical rating

Type

Temp

wetside

°C

Low

Temp

use

AC max. values AC max. values

VA Volts Amps Watts Volts

Res

amps

Ind

amps

D4, D8 400 Amp. 2000 440 5 50 250 5 0.5

X4, X8 250 Amb. 2000 440 10 50 250 10 0.5

P4, P8 400 Amb. 6 250 0.25 3.6 250 0.25 0.1

H4, H8 250 -100°C 2000 400 5 50 250 5 0.5

Power factor

0.4 mm

Time constant

40ms max.

Warning

Gold plating on the contacts of the P4 and P8 switch mechanisms may be

permanently damaged if the mechanisms are used to switch circuits with

values greater than those shown above.

Important wiring notes

1. To minimize the electrical shock hazard, before energizing it is essential

that the equipment is connected to a protective ground using the terminals

supplied.

2. Switches must not be used for the direct starting of motors. Contacts

should be wired in series with the operating coils of relays, contactor starters

or solenoid valves, and fused separately.

3. The temperature of the switch enclosure may at times approach the

temperature of the process and suitable heat resisting cables should

therefore be used, together with appropriate cable glands.

4. A sufficient length of flexible cable should be fitted to allow easy removal

of the switch head and displacer assembly at any time.

Flameproof models

5

. Cable entry must be fitted with a flameproof cable entry device, with or

without thread adaptor, and should be used in accordance with a local Code

of Practice subject to agreement by the local Inspecting Authority.

6. U.L. Approved Applications: Use copper conductors 60°/75°C: 140°/167°F

ONLY. Torque terminals to 6kg/cm: 7lb/in.

7. Ensure the cover locking safety grub screw is replaced and tightened

before energizing.

Two switch pump control circuit using

a

uxiliary contacts on starter.

Note diagram shows starter fitted with

250V coil for 3-phase 3-wire supply

connect coil terminal N to line 1 and fit

440V coil.

Two switch pump control circuit using

‘

holding’ relay for starters without

auxiliary contacts.

Single-switch Control

Two

-

Switch Control

Combined Pump Control

And Low Level Alarm

Two

-

switch Control

High and Low Level Alarm

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

Alarm ON

Alarm ON

Alarm ON

Alarm ON

Alarm ON

Pump ON

HLA Switch

LLA Switch

Pump Control Switch

LLA Switch

As high level

alarm

As low level alarm