9

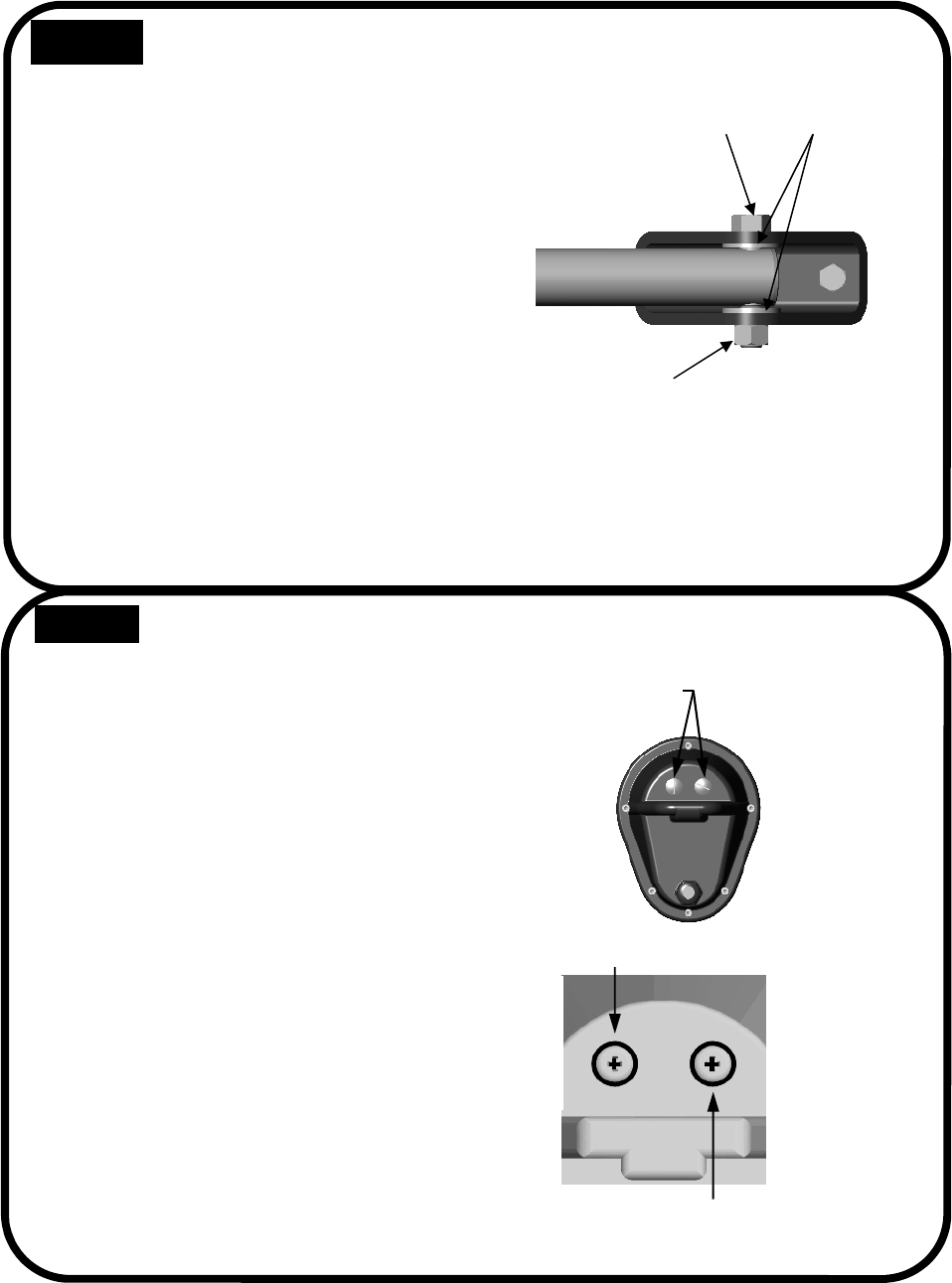

STEP 6

Limit Switch Adjustment

To Retract More

Turn Retract Limit

Screw Clockwise

To Retract Less

Turn Retract Limit

Screw Counter-

Clockwise

To Extend More

Turn Extend

Limit Screw

Counter-

Clockwise

To Extend Less

Turn Extend

Limit Screw

Clockwise

Remove limit switch end caps

Cycle the operator and adjust limits as

required. If the operator opens

automatically after closing, extend less

until gate remains closed.

Do not retract the extension tube too far

or the retract limit switch will not be

activated. (You can depress the LED

ENABLE button on the control board to

see when the actuator has reached it’s

limit)

1650 Adjustments

As you open and close the gates, you

will notice that the slave side moves 2-3

seconds slower than the master.

Tip: By welding stop tabs on the top

and bottom of the master side, the two

gates may now be adjusted so the slave

gate will close against the stop tabs of

the master gate and create enough

tension to prevent gates from moving

back and forth.

STEP 5 GATE BRACKET INSTALLATION

Activate push button on the side of the control box and

extend the actuator until it stops (PULL TO OPEN only,

leave actuator retracted for PUSH TO OPEN).

WARNING: Do not let extension tube rotate as it

extends. Do not insert fingers or tools in the hole at

the end of the extension tube

Align the hole in the end of the actuator extension tube

with the holes in the gate bracket and locate gate

bracket mounting position with the gate in the closed

position. Weld or bolt the gate bracket to the gate using

3/8” bolts, lock washers, and nuts.

Tip: Tack weld or C clamp at first if uncertain about

location. Run the unit through a complete cycle to

insure proper operation then mount permanently .

Bolt the actuator to the gate bracket as shown.

1/2” x 3”

Bolt

1/2” Lock Nut

1/2” Washer

(2 places)

Extend Limit Screw

Retract Limit Screw

IMPORTANT

Never weld parts to the gate or posts when the operator circuit board is powered. Doing so may

damage the board beyond repair.