8

For efficient mowing!

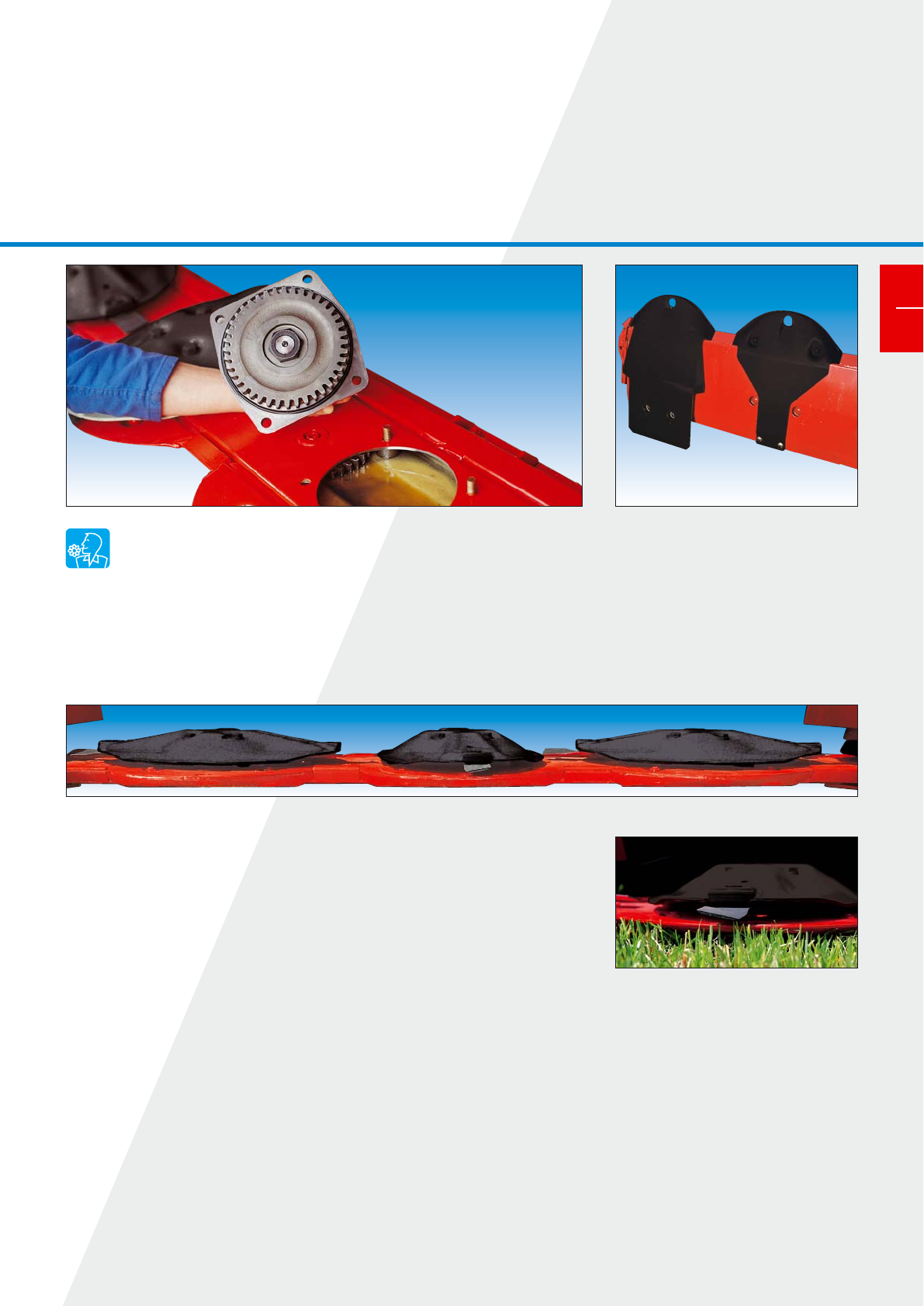

Disc bearing stations

- Fast and easy removal and installation of the disc bearing station.

- For maximum reliability and minimum down time, the stations which include the

housing, bearing and pinion shaft are factory-assembled.

KUHN’s oval disc design offers the following advantages:

- Better evacuation of the cut forage to the conditioning rotor: no jamming

- Greater knife overlap for a cleaner cut in a greater range of crop conditions

- A bent knife cannot contact a neighbouring disc

- Reduced risk of foreign objects getting caught between two discs.

Compact, streamlined cutterbar...

- For cleaner forage: The cutterbar is very flat and streamlined to stop earth or plant

debris accumulating,

- Less need for power: excellent penetration into even the densest forage,

- Full use is made of the whole mowing width: the drive takes place at the first disc on the

tractor side.

Cutterbar protection

Extra rigidity is ensured with the cutterbar

gearcase mounted inside a steel cradle

with a rear stiffener. One-piece disc

guards and skid shoes are made of heat-

treated steel to protect the discs.

Knives

- KUHN knives are made of high quality

steel and manufactured to very strict

standards!

- For safety and long life, knives are atta-

ched with specially designed hardware,

not “quick fastening” devices.

It’s easy to change or turn the discs,

thanks to direct access to each skid.

Very flat and smooth cutterbar that reduces soil or crop residues building up