Repair

311327E 13

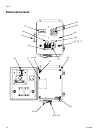

3. Remove four bolts (117) to remove entire air motor

assembly.

4. Remove lock nut (118) from piston rod (138) and

remove pump yoke (122).

5. Remove four lock nuts (118), washers (116), and

tie-rod bolts (117).

6. Lift top plate (115) and remove from air cylinder

(114).

7. Push piston rod assembly out of air cylinder and

replace piston o-ring (139) and lubricate.

8. Remove nut (177). Replace bottom plate bearing

(135), u-cup seal (136), and lubricate. Ensure the

open end of the u-cup seal faces up.

9. Replace top and bottom o-rings (140) in plates. Use

lubricant to hold in place.

10. Assemble in reverse order.

11. Torque tie rod bolts in small increments evenly to

17-22 in-lbs (3•4 Nm).

Primary Heater

1. Turn Main Disconnect Switch OFF.

2. Perform Pressure Relief Procedure, page 5.

3. Wait for heater to cool.

4. Perform Flushing, page 5.

Removal

1. Disconnect two fluid lines at bottom of heater.

2. Disconnect upper fluid hose from fittings.

3. Remove two side screws from thermostat cover.

4. Disconnect two main power leads from wire

harness.

5. Remove four screws underneath heater. Retain four

thermal barrier spacers for later installation.

6. Pull heater assembly out and remove from unit.

Service

See Parts on page 16 for servicing.

Installation

Reconnect and install primary heater in reverse order of

removal steps.

Fluid Inlet Filter Screen

A Y-line filter screen before each proportioning pump

traps solid matter to ensure proper operation of ball

check valves in pump base. Inspect and clean both

screens. See Predator Proportioner Operation manual

(311326).

Read Warnings on page 3. Wait for heater to cool

before repairing.

TI9513b

117

115

114

138

118

122

135

136

140

139

177

Regularly clean isocyanate pump screen during

start-up procedure. This minimizes moisture con-

tamination problems by immediately flushing out

any isocyanate residue at start of dispensing oper-

ation.

TI9516a