10

6500-065-K-7-08

SECTION 1 - INSTALLATION

Prior to beginning the installation of the swing gate operator, we suggest that you become familiar with the

instructions, illustrations, and wiring guide-lines in this manual. This will help insure that your installation is

performed in an efficient and professional manner.

The proper installation of the vehicular swing gate operator is an extremely important and integral part of the

overall access control system. Check all local building ordinances and building codes prior to installing this

operator. Be sure your installation is in compliance with local codes.

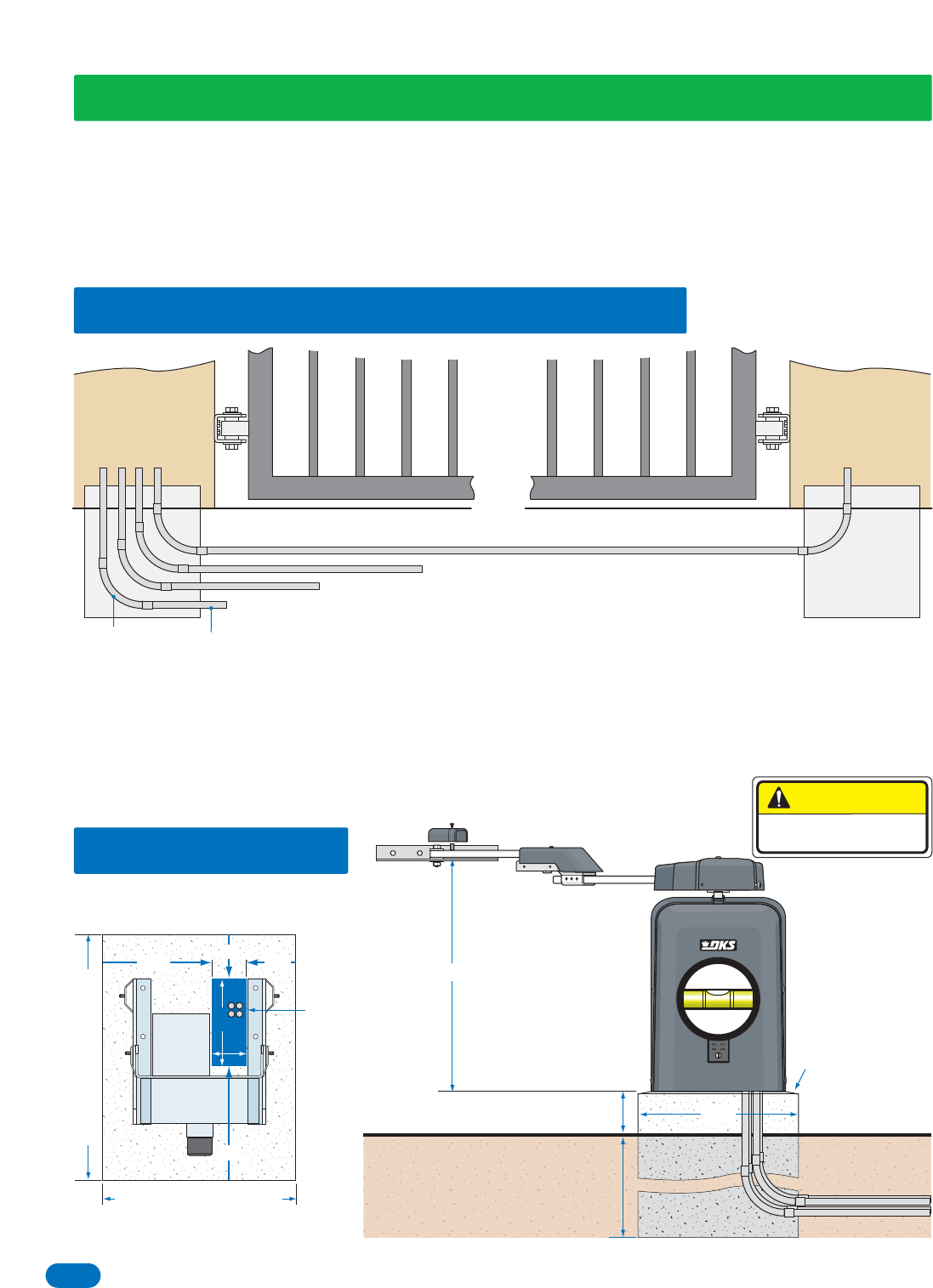

1.1 Underground Conduit Requirements

1.2 Concrete Pad

• The conduit requirements are for a typical swing gate operator installation (the secondary operator is shown for

those applications where a secondary operator may be used). The conduit requirements for your application may

vary from this depending on your specific needs.

• Use only sweeps for conduit bends. Do not use 90° connectors as this will make wire pulls very difficult and can

cause damage to wire insulation.

• We suggest that minimum 3/4-inch conduit be used.

• Be sure that all conduits are installed in accordance with local codes.

Low Voltage Control and/or P.A.M.S. Wires

Primary/Secondary Interconnection Cable (Dual Operator Application Only)

Loop Lead-In Wires

High Voltage Power

Sweeps

Concrete Pad

3/4 Inch Minimum

Primary

Operator

Position

Secondary

Operator

Position

Underground depth of the concrete

pad is determined by soil conditions

and local building codes. Reinforced

concrete recommended.

22” Concrete Pad Width

28” Concrete Pad Length

Concrete pad

MUST be level.

Note: Bevel the

edges of concrete

pad to eliminate

water puddling

under the operator.

4” minimum

31”

Conduit Area

Conduit Location

Back-up

Motor

Plate

Electronics

Box

4”

10”

22”

Approximate

Conduit Position

CAUTION

NEVER REMOVE HUB

after manual release.

5”

13”

5.5”12.5”