4

Tamping

When inlaying pavement markings in new asphalt

concrete surfaces, tamp the markings during the

final compaction (finishing roller) of the mat.

After application of markings on existing surfaces,

tamp the tape thoroughly with the 3M™ Roller

Tamper Cart (RTC-2) with a minimum 200 lb.

(90 kg) load, or slowly (2-3 mph) drive over the

tape three times with a vehicle tire. The vehicle

must be equipped with a pointing device to aid in

keeping the vehicle on the tape, making three

passes forward over the tape. Use a vehicle tire on

long line markings only. Do not attempt to tamp

intersection markings with a vehicle tire.

Tamping is most important!

When using the RTC-2 Roller Tamper Cart with

200 lbs. (90 kg.) of weight:

• Do not twist or turn the tamping device on the

tape.

• Make three passes back and forth over each part

of the tape.

• When tamping symbols, start in the center and

work to the outside edges.

• Make sure all edges are firmly adhered.

• Open road to traffic as soon as tamping is

complete.

Maintenance

Keep All Fasteners Tight

Lubrication:

All the pivot points and sliding areas

should be kept lubricated with light oil penetrant

such as 3M™ Five-Way Penetrant or similar pene-

trants such as WD-40.

Cleaning: The rubber application roller wheels

and cutting mechanism must be kept clean. 3M™

Citrus Base Industrial Cleaner or any natural citrus

based cleaner may be used on the wheels and

knives. Solvents may be used occasionally for dif-

ficult cleaning problems. A spray bottle of cleaner

is useful to prevent asphalt buildup on the wheels

and adhesive buildup on the knives during opera-

tion.

Caution: Do not use solvents or petroleum prod-

ucts on the silicone application roller when work-

ing on new, hot asphalt surfaces. A paint scraper or

putty knife should be used to clean the asphalt

buildup from the scraper and cutter mounting bar.

To prevent asphalt buildup around the roller, addi-

tional clearance can be provided by loosening the

scraper mounting screws and sliding the scraper

back. Tighten the screws. Second, remove the cut-

ter mounting bar and grind 1/8 inch (3.175 mm)

off the bottom. Replace the bar.

Each Every 50 Every 100

Use Hour Hours

Engine Oil Check Level X X

Change*

Air Cleaner Check X X

Clean*

Spark Plug Clean and X

Readjust

*Service more frequently when used in dusty areas.

Adjustments

The SCRAPER BAR, which is readjusted by the

manufacturer to prevent excess materials from ac-

cumulating on the application roller, should be pe-

riodically checked for wear and rotated if neces-

sary. The bar should contact the rubber roller

across the full length of the roller.

The KNIVES are readjusted by the manufacturer

to slide across each other with a minimum of fric-

tion in a scissors action. Adjustment is needed

when foil construction tapes are not cleanly cut.

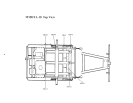

Either the STATIONARY KNIFE or the SLIDING

KNIFE may be adjusted (See Figure 5). To adjust

the stationary knife, loosen the mounting screws

slightly. Turn the set screws to bring the cutting

edge down, and retighten the mounting screws.

The same procedure is followed to adjust the slid-

ing knife. Each knife has two cutting edges. The

knives may be removed and new cutting edges

exposed. The knives may be sharpened after the

cutting edges are dull.

Figure 5