PAGE 18 — MGX SERIES • OPERATION AND PARTS MANUAL — REV. #0 (03/26/12)

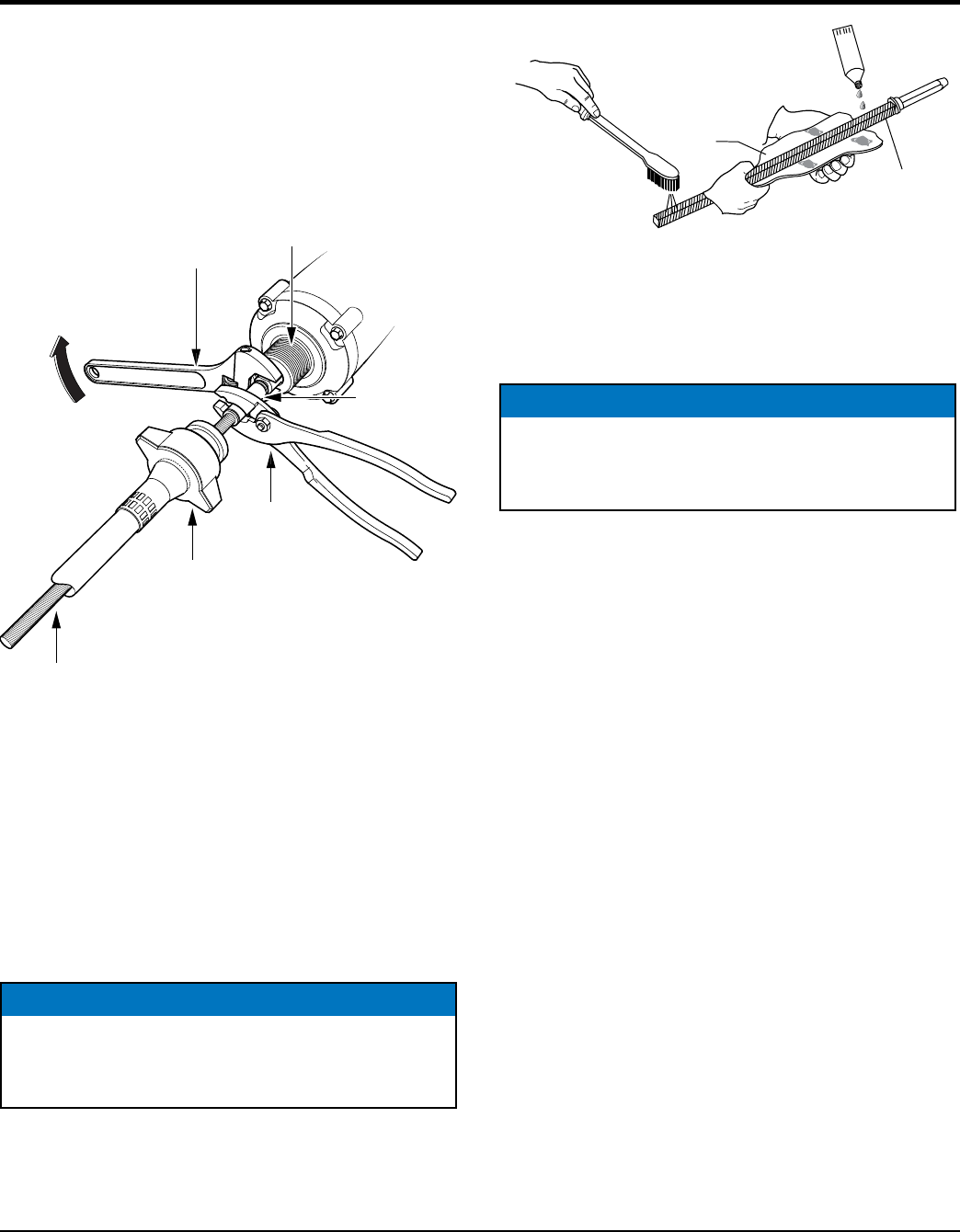

4. Place a 5/16-inch wrench on the flat side of the motor

shaft coupling.

5. Using a pair of pliers, grip the flex shaft core crimp.

6. Turn the motor coupling clockwise with the wrench to

remove shaft from motor.

Figure 10. Removing Shaft from Motor

7. Slowly pull the wire core from the shaft.

8. Inspect the core for broken wires, permanent set or

other damage such as an area that indicates high wear

or having overheated. If any of these conditions exist,

replace shaft/head assembly.

9. Use the core to push a cleaning patch through the

casing to remove any old grease or foreign matter that

may have accumulated inside the casing.

10. Thoroughly clean wire core (Figure 11) if it is being

reused. A wire brush may be required to remove

hardened residue.

Wrench

Motor Threaded

Connector

Pliers

Flex Shaft Core

Flex Shaft

Core Crimp

Plastic Coupler

NOTICE

DO NOT use solvents to clean casing. Applying solvents

to the core or casing may cause grease (lubricant) to

breakdown, resulting in damage to the shaft.

Figure 11. Cleaning Wire Core

11. Apply a light amout of DuBois "TPG" lubricant (Figure 11)

or a good grade bearing grease to the entire length of

the wire core.

12. Reinstall wire core back into casing.

13. Align the flexible shaft core to the motor shaft.

14. Using a pair of pliers, grip the flex shaft core crimp.

15. Place a 5/16-inch wrench on the flat side of the motor

shaft.

16. Turn the motor coupling counterclockwise with the

wrench until tight.

17. Align and push the flexible shaft into the motor threaded

connector.

18. Tighten the plastic coupler making sure shaft/head

assembly is connected securely to the motor.

TPG

LUBRICANT

WIRE

CORE

CLOTH

WIRE

BRUSH

NOTICE

DO NOT force casing full of grease. A tightly packed

casing will load the drive motor which could lead to

overheating.

MAINTENANCE