Page 4 of 8 66506-B (en)

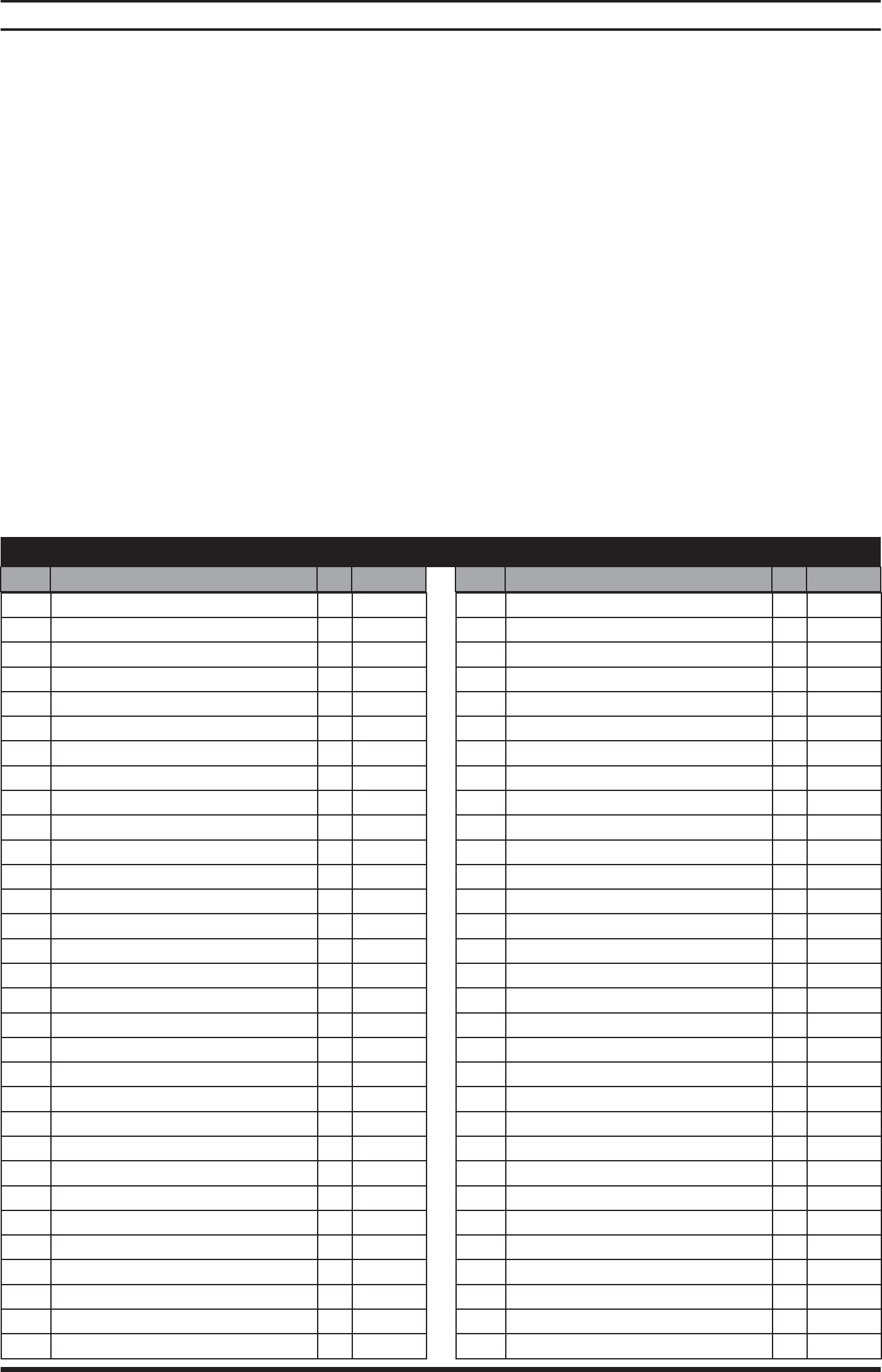

PARTS LIST

Item Description

(size)

Qty Part No. Item Description

(size)

Qty Part No.

9

1 "O" Ring

(1/16" x 5/16" o.d.)

(1) Y325-8

2 Piston Assembly

(includes items 2a and 2b)

(1) 66654

2a Washer (1) 92524

2b Piston (1) 92520

9

3 “O” Ring

(3/32” x 5/8” o.d.)

(1) Y325-111

9

4 Washer (1) 92517

5 Extension Rod (1) 92519

6 Cylinder (1) 92513

9

7 “O” Ring

(1/16” x 7/8” o.d.)

(2) Y325-18

8 Cap Screw, Hex Head

(5/16” - 18 x 7/8”)

(1) Y6-54-C

9 Washer (1) F15-44-C

9

10 “O” Ring

(1/16” x 1/2” o.d.)

(1) Y325-12

11 Piston (1) 92521

9

12 “U” Cup Packing

(3/16” x 1-5/8” o.d.)

(1) Y186-53

13 Gland (1) 94789

9

14 “U” Cup Packing

(3/16” x 1-1/2” o.d.)

(1) Y186-52

9

15 “O” Ring

(3/32” x 2-1/16” o.d.)

(5) Y325-134

16 Washer (1) 94790

17 Spacer (4) 93250

9

18 “O” Ring

(1/8” x 1-3/4” o.d.)

(4) Y325-222

19 Washer (4) 93251

20 Spool (1) 92522

22 Head Plate (1) 90056-1

9

24 “U” Cup Packing

(1/8” x 11/16” o.d.)

(1) Y186-46

25 Pipe Plug

(1/8 - 27 N.P.T.)

(2) Y227-2-L

26 Cap Screw, Socket Head

(3/8” - 16 x 2-1/2”)

(10) Y99-68

27 Block (1) 92514

9

28 “O” Ring

(1/16” x 5/8” o.d.)

(1) Y325-14

9

29 “O” Ring

(3/32” x 1-7/8” o.d.)

(1) Y325-131

30 Block Manifold (1) 92515

31 Cap Assembly

(includes items 31a and 31b)

(1) 66655

31a Cap (1) 92531

31b Washer (1) 92516

32 Cap Screw, Socket Head

(1/4” - 20 x 1-3/4”)

(4) Y99-45

9

33 “O” Ring

(1/16” x 1-1/4” o.d.)

(3) Y325-24

34 Tube (1) 92518

35 Pipe Plug

(1/8 - 27 N.P.T.)

(1) Y227-2-L

9

36 “O” Ring

(1/8” x 11-3/4” o.d.)

(2) Y325-277

37 Air Cylinder (1) 90035

38 Pipe Plug

(1/16 - 27 N.P.T.)

(1) Y227-1-L

39 Valve Rod (1) 92527

40 Retaining Ring

(2.630” o.d.)

(1) Y147-237

9

41 “U” Cup Packing

(1/4” x 1-3/4” o.d.)

(1) Y186-24

42 Ball

(0.4375” dia.)

(1) Y16-14

43 Piston Assembly (1) 62111-B

44 Guide Washer (1) 92216

45 Spring (1) 24143-B

46 Air Motor Base Ass’y

(includes items 46a and 46b)

(1) 66507-1

46a Air Motor Base (1) 90034

46b Bushing (1) 92511

47 Nut

(1/2” - 20)

(8) Y11-8-C

48 Screw (1) 92525

49 Cap Screw, Hex Head

(1/2” - 20 x 10-1/4”)

(8) 94046-1

9

50 “O” Ring

(1/4” x 12” o.d.)

(1) Y325-452

51 Spacer (1) 92860

52 Connector (1) 93006

9

Cotter Pin

(1/8” x 2”)

(1) Y15-47-C

9

Gadus® S2 U1000 Grease Packet (1/4 oz.) (1) 94833

9

Items included in service kit 637112

Service Kit

(entire valve section)

637113

Items not included with 66506-B air motor

Assemble one (15) “O” ring and the (16) washer into the

(30) block manifold and against the (13) gland (see gure

5).

Assemble four (15) “O” rings, four (18) “O” rings, four (17)

spacers and four (19) washers into the (30) block mani-

fold (see gure 5). NOTE: Assemble the (19) washers with

the i.d. lips toward the (18) “O” ring. Position the (17)

spacers so the legs are not aligned with the 3/4 - 14 N.P.T.

exhaust ports in the (30) block manifold.

Clean the threads in the (20) spool.

Apply grease to the exterior of the (20) spool and assem-

ble it into the (30) block manifold. Align the slot in the (20)

spool with the 3/4 - 14 N.P.T. exhaust port in the side of

the (30) block manifold.

Assemble the (51) spacer into the (31) cap assembly and

assemble the (31) cap assembly to the (30) block mani-

fold, securing with four (32) cap screws.

Assemble the (12) “U” cup into the groove in the (11)

piston, with the lips pointed toward the “boss” side of the

piston.

Assemble the (10) “O” ring onto the boss portion of the

(11) piston.

Clean the threads on the (8) cap screw.

21.

22.

23.

24.

25.

26.

27.

28.

Assemble the (8) cap screw and (9) washer thru the (11)

piston.

Apply Loctite 271 to the threads of the (8) cap screw then

thread it into the (20) spool.

Insert a 1/4” rod or similar device thru the 3/4 - 14 N.P.T.

exhaust port in the side of the (30) block manifold and

thru the slot of the (20) spool to prevent it from rotating,

then tighten the (8) cap screw. Remove the 1/4” rod.

Assemble the (28 and 29) “O” rings into the (30) block

manifold.

Assemble the (27) block to the (30) block manifold, se-

curing with four (26) cap screws (hand tight only).

Assemble two (33) “O” rings to grooves in the (34) tube.

Assemble the (34) tube into the port provided in the (46)

air motor base assembly.

Assemble one (33) “O” ring to the counterbore in the bot-

tom of the (30) block manifold.

Lubricate the bore in the (27) block.

Carefully slide the (27 and 30) block assemblies down

over the (2) piston assembly and (34) tube and onto the

(22) head plate.

Assemble six (26) cap screws in the (27 and 30) block

assemblies. Tighten the two (26) cap screws in the (27)

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39

.

DISASSEMBLY / ASSEMBLY

(continued on page 6)