PAGE 7 OF 86564XĆX

FIGURE 8

36 WASHER GROOVE

40 EXTENSION ROD

32. Pull the (42) piston adapter up around the (36) washer.

33. Place the (16) washer over the (40) extension rod and into the (42)

piston adapter.

34. Clean with solvent and put Loctite 271 on the threads of the (31)

valve piston. Screw the (31) valve piston into the (42) piston adapter

and tighten (see figure 3).

35. Push the assembled (42) piston adapter and (31) valve piston down

thru the 90350 installation tool until they bottom.

36. Remove the 90350 installation tool.

37. Install the (37) upper gland over the (31) valve piston and push

down, being careful to retain the (38) seal in the O" ring groove.

38. Align the two bolt holes and secure the (37) upper gland to the (18)

head assembly with the two (6) machine screws and two (7) lock

washers (see figure 9).

39. Insert the (12) insert spring assembly in the (18) head assembly,

with the hooks down and the nylon roller toward the (31) valve piston

(see figures 2 and 9).

40. Thoroughly grease and insert the (34) pilot insert, two (35) valve

guides, (33) valve plate and (32) gasket into the (18) head assembly

(see figure 9).

41. Thoroughly grease and insert the (13) valve insert into the (18) head

assembly (see figure 2).

42. Thoroughly grease and insert the (14) gasket and the (11) valve

plate and pin assembly between the (13) valve insert and the (18)

head assembly, with the two pins in the (11) valve plate and pin asĆ

sembly up (see figures 2 and 9).

43. Hook the round coils in the (12) insert spring assembly over the pins

in the (11) valve plate and pin assembly (see figure 9).

44. Hook the bottoms of the (12) insert spring assembly into the holes on

the side of the (11) valve plate and pin assembly.

45. Insert the (9) valve guide against the face of the (11) valve plate and

pin assembly. The legs of the (9) valve guide should be down, with

the leg having the threaded hole the farthest from the bottom toward

the air inlet in the (18) head assembly.

46. Insert and tighten across corners of eight (4) machine screws and

eight (5) washers (see figures 1 and 9).

47. Thoroughly grease and install the (10) gasket in the (8) air motor

cap.

48. Place the (8) air motor cap on the (18) head assembly and secure

with the six (3) screws (see figure 2).

49. Place the (2) deflector on exhaust port of the (18) head assembly,

with the opening down, and secure with four (1) machine screws

(see figure 2).

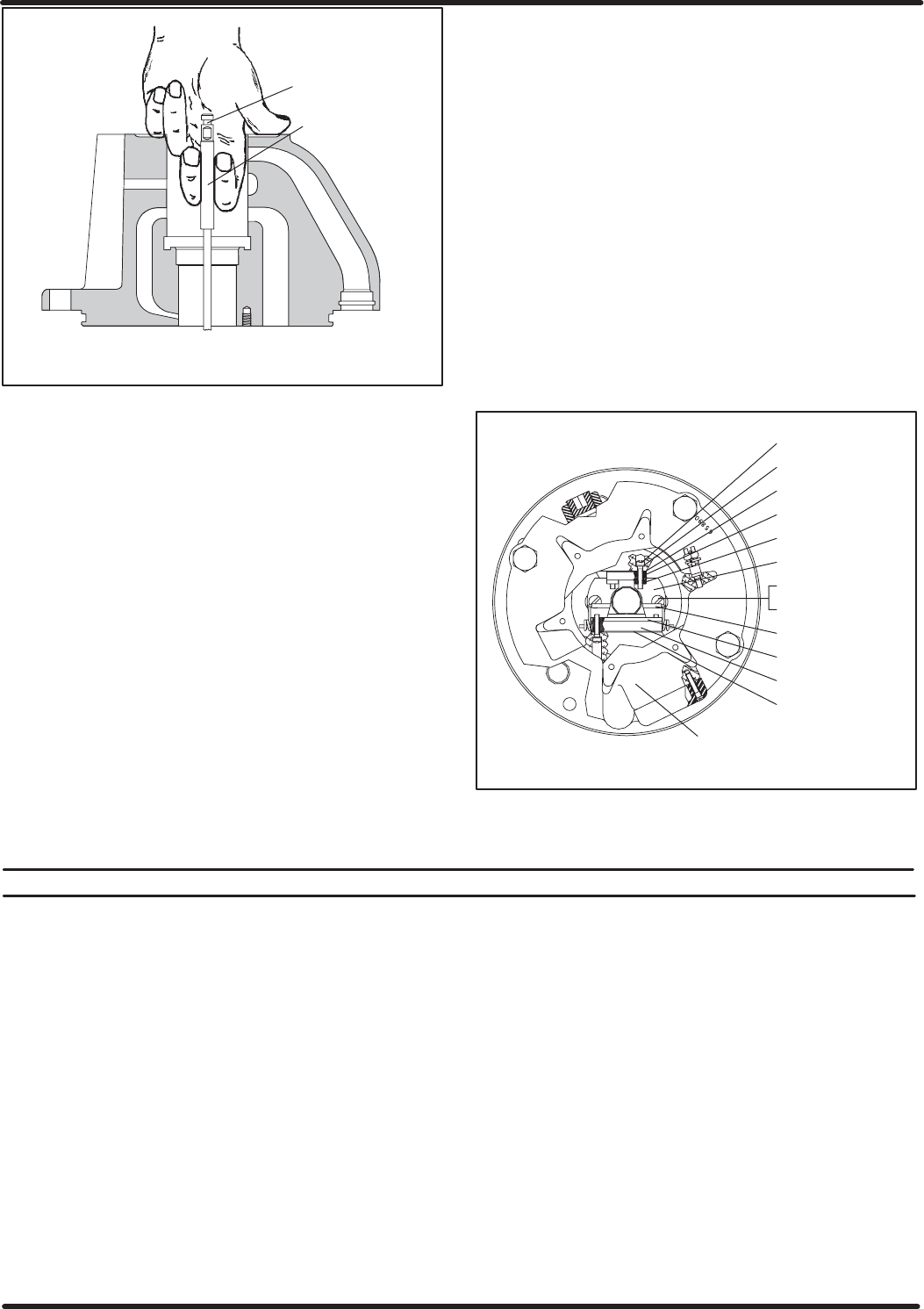

FIGURE 9

32 GASKET

33 VALVE PLATE

35 VALVE GUIDE (2)

37 UPPER GLAND

6 SCREW (2)

7 LOCK WASHER (2)

12 SPRING ASS'Y

9 VALVE GUIDE

11 VALVE PLATE

14 GASKET

18 HEAD ASSEMBLY

5 WASHER (8)

4 SCREW (8)

TROUBLE SHOOTING

PROBLEM

Air leakage out of main exhaust.

CAUSE

Worn (13) valve insert.

REMEDY

Replace (13) valve insert.

CAUSE

Worn (11) valve plate and pin assembly.

REMEDY

Replace (11) valve plate and pin assembly.

CAUSE

Damaged (23) piston assembly.

REMEDY

Replace (23) piston assembly.

PROBLEM

Continual air leakage out of bleeder hole in (18) head assembly.

CAUSE

Worn (15) O" ring or (38) seal.

REMEDY

Replace (15) O" ring and (38) seal.

PROBLEM

Air leakage around (52) piston rod.

CAUSE

Worn (49) U" cup.

REMEDY

Replace (49) U" cup.