600876_0706

and repair the source of ingested dirt.

6. Never operate a machine without an air filter installed.

Super Z liquid cooled/Super Z Diesel

The Super Z liquid cool tractor and Super Z Diesel are equipped with a

safety filter. The filter element slides over the safety filter.

NOTE: The safety filter does not require servicing unless it becomes

contaminated with dirt or moisture.

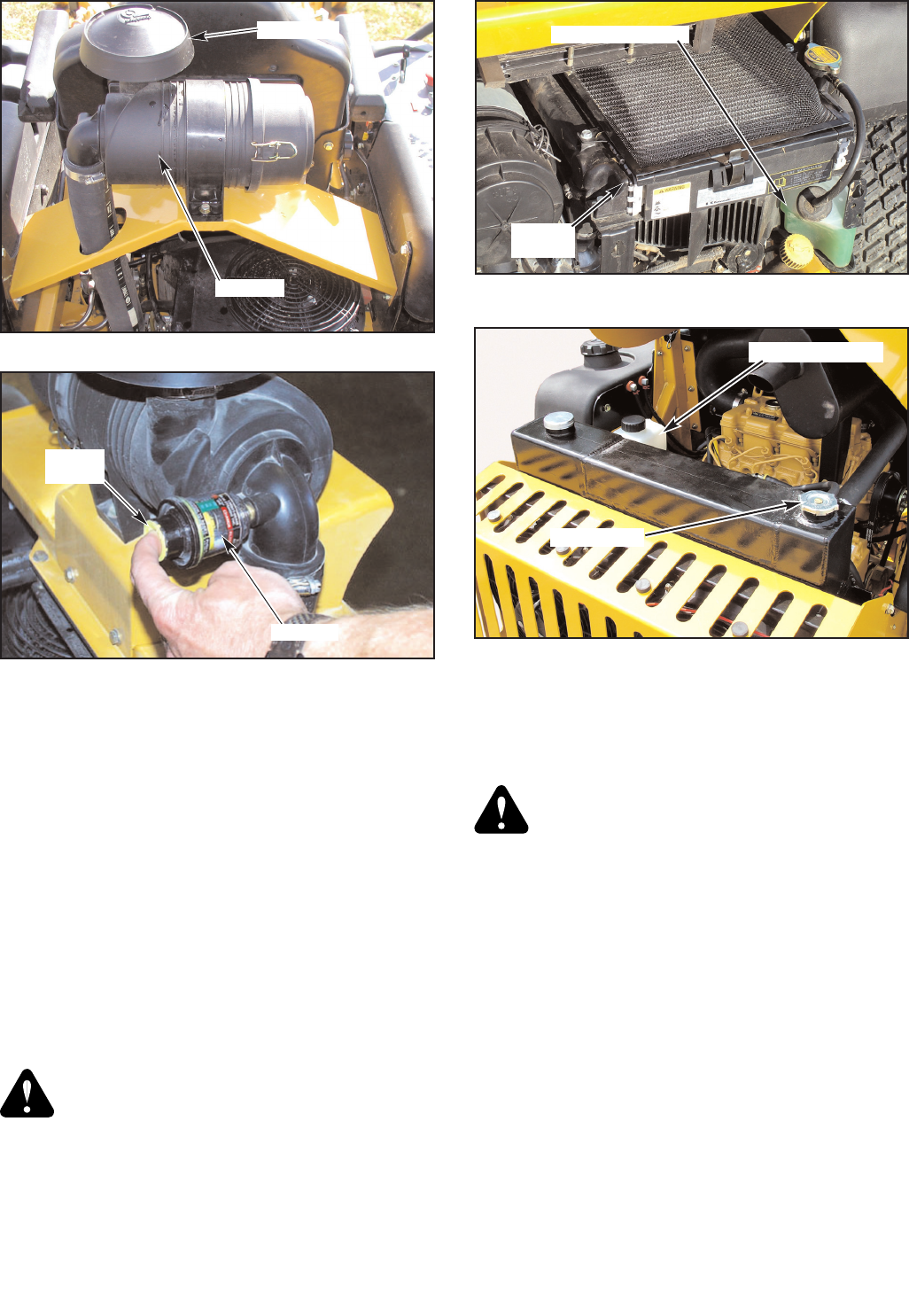

Air restriction indicator

Some Hustler units have an air restriction indicator installed in the air

cleaner. Fig. 4-6

Replace the element whenever the restriction indicator shows reaches the

change filter red line. Check the indicator daily and replace element as

needed or annually whichever occurs first.

Reset the indicator by pushing in on the yellow button after each element

change. Fig, 4-6

Cooling system

Super Z liquid cooled

DANGER: Never remove radiator cap or overflow reservoir

cap when engine is hot. Pressurized hot steam and water may

be released, causing serious burns or possible blindness.

Engine cooling is accomplished with circulated water and Ethylene

Glycol mixture. The radiator is equipped with a pressure cap and overflow

reservoir. Follow the information found in the engine owner’s manual for

the recommended coolant solution.

Visually inspect the system daily prior to operating tractor. Be sure the

engine is level. Check the coolant level only when the system is cold.

Check the coolant level only at the overflow reservoir (Fig. 4-7). The

cooling system is a closed type. Never open the radiator cap. Doing so

may induce air into the cooling system and may cause overheating. The

coolant level should be between the “H” and “L” marks.

Super Z Diesel

DANGER: Never remove radiator cap or overflow reservoir

cap when engine is hot. Pressurized hot steam and water may

be released, causing serious burns or possible blindness.

Engine cooling is accomplished with circulated water and Ethylene

Glycol mixture. The radiator is equipped with a pressure cap and recovery

tank. A 50-50 mixture is recommended for all season operation. This

mixture provides freeze protection to -32 degrees F (-35 degrees C).

Should temperatures fall below this level, additional Ethylene Glycol must

be added to the mixture.

Visually inspect the system daily prior to operating tractor. Check

coolant level in the recovery tank located to the front left of the radiator

assembly (Fig. 4-8). When the engine is cold there should be 1” (2.54 CM)

of coolant in the recovery tank. When adding coolant, pre-mix the solution

before adding it to the recovery tank. It is not necessary to remove radiator

cap for adding small amounts of coolant to system.

General engine maintenance

Detailed instructions and recommendations for break-in and regular

maintenance are specified in the Engine Owner’s manual. Please refer to

this manual for engine servicing, lubricating oil levels with quality and

viscosity recommendations, bolt torques, etc. The engine warranty is

backed by the manufacturer. Special attention should be paid to applicable

data which will not be duplicated here.

IMPORTANT: Refer to the Kohler EFI engine owner’s manual for

specific cleaning instructions.

Figure 4-7

Overflow reservoir

Radiator

Screen

Figure 4-8

Overflow reservoir

Radiator cap

Figure 4-6

Indicator

Reset

button

22

Figure 4-5

Pre-cleaner

Canister