Shutdown

28 312765B

Shutdown

Short-Term Shutdown

1. Turn off proportioner. Refer to proportioner manual

for shutdown procedure. See Related Manuals on

page 3.

2. Relieve chemical pressure. See Pressure Relief

Procedure on page 26.

3. Properly seal supply drums.

4. Ensure desiccant dryer is in proper working condi-

tion.

5. Turn off air compressor.

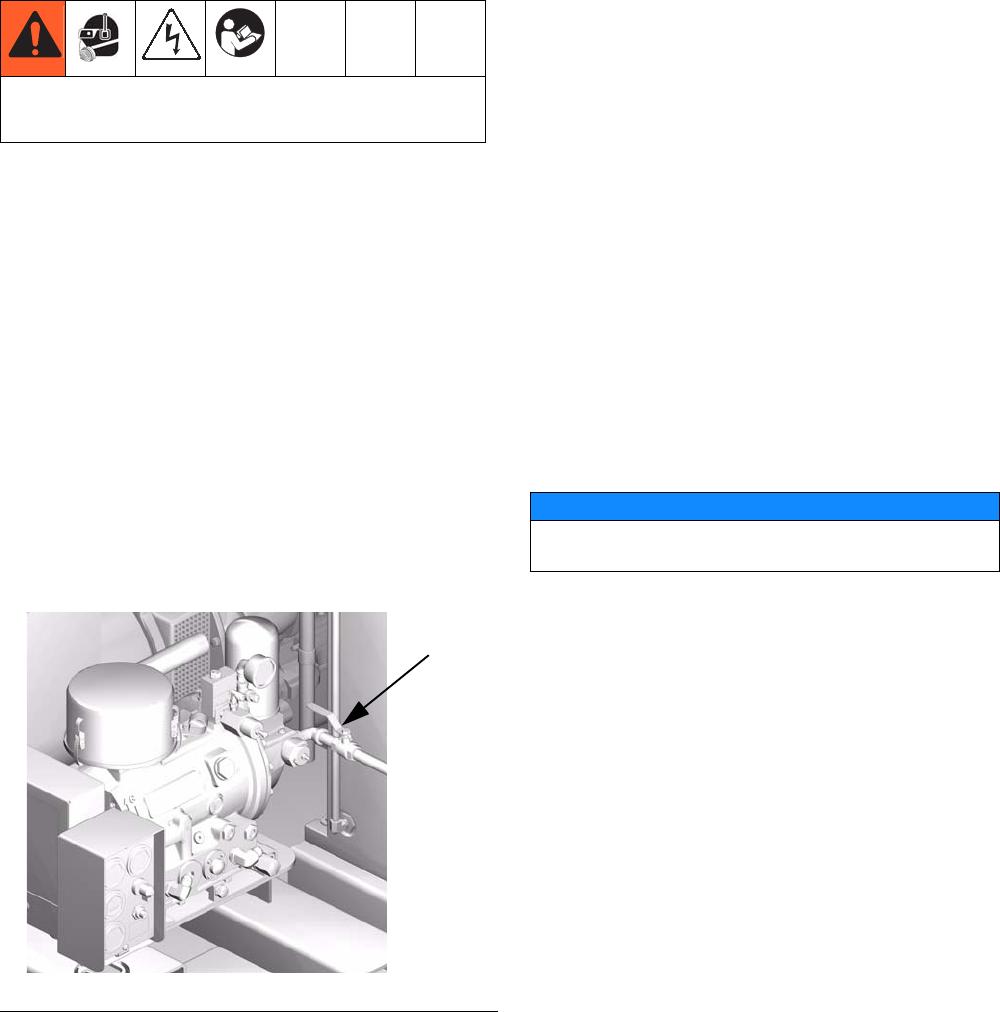

• For screw compressors, close the ball valve.

See F

IG. 17, ball valve is shown open.

• For all other compressors, turn switch on

starter to the off position.

6. Relieve air pressure. See Pressure Relief Proce-

dure on page 26.

7. Turn off main breaker.

8. Run generator unloaded for at least two minutes to

allow engine to cool. See generator operator’s man-

ual for details.

9. Turn generator ignition switch to the off position.

10. Turn Shore/Generator Power Switch (AF) to the

“OFF” position.

Long-Term Shutdown

NOTE: Perform long-term shutdown when Spray Rig will

not be used for longer than 90 days.

1. Follow steps 1 through 7 of Short-Term Shutdown.

2. Flush pump, feed system hoses, proportioner, and

spray gun with mesamoll or compatible solvent. Fol-

low flushing procedure in each component’s man-

ual. See Related Manuals on page 3.

3. Remove pumps, agitators, and supply hoses from

feed system.

4. Clean agitator with mesamoll or compatible solvent.

5. Cap off the drums to provide air-tight seal.

6. Turn Shore/Generator Power Switch (AF) to the

“OFF” position.

7. Follow long-term storage procedure in compressor

manual.

8. Follow long-term storage procedure in generator

manual.

See shutdown instructions and related warnings in

supplied manuals. See Related Manuals on page 3.

F

IG. 17: Screw Compressor Ball Valve

TI12894a

NOTICE

Isocyanate crystallization may result if proper flush-

ing is not performed.